Cod. 598144

Rev. 12/1218

Operating Instructions Manual for

VENDED washers

GIRBAU, SA

Crta de Manlleu, km. 1

08500 VIC (Barcelona) • SPAIN

National sales:

T.(+ 34) 902 300 359

International sales:

T.(+ 34) 938 862 219

Service:

T.(+ 34) 902 300 357

www.girbau.es

For USA and CANADA:

CONTINENTAL GIRBAU Inc.

2500 State Road 44

WI 54904 Oshkosh • USA

Tel. 1(920) 231-8222

www.continentalgirbau.com

EN

COIN

CONTROL

PROFIT PLUS

CONTROL

HS-6/EH

RMS/RMG/REM

Cod. 598144

Rev. 12/1218

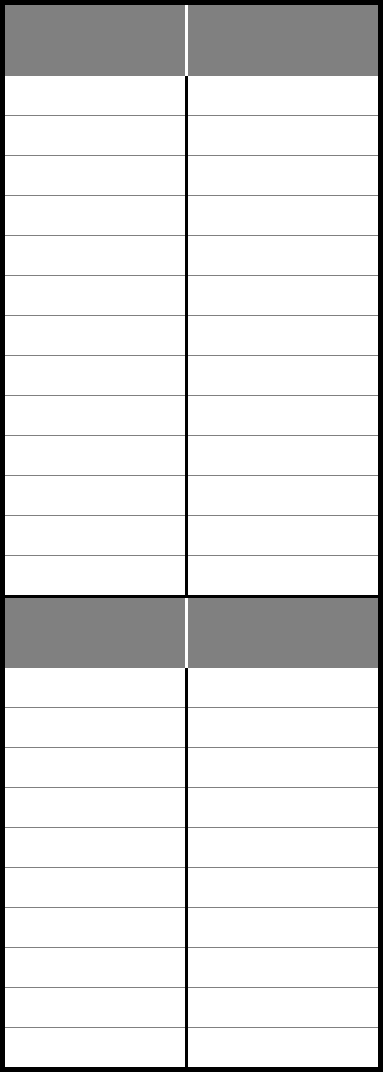

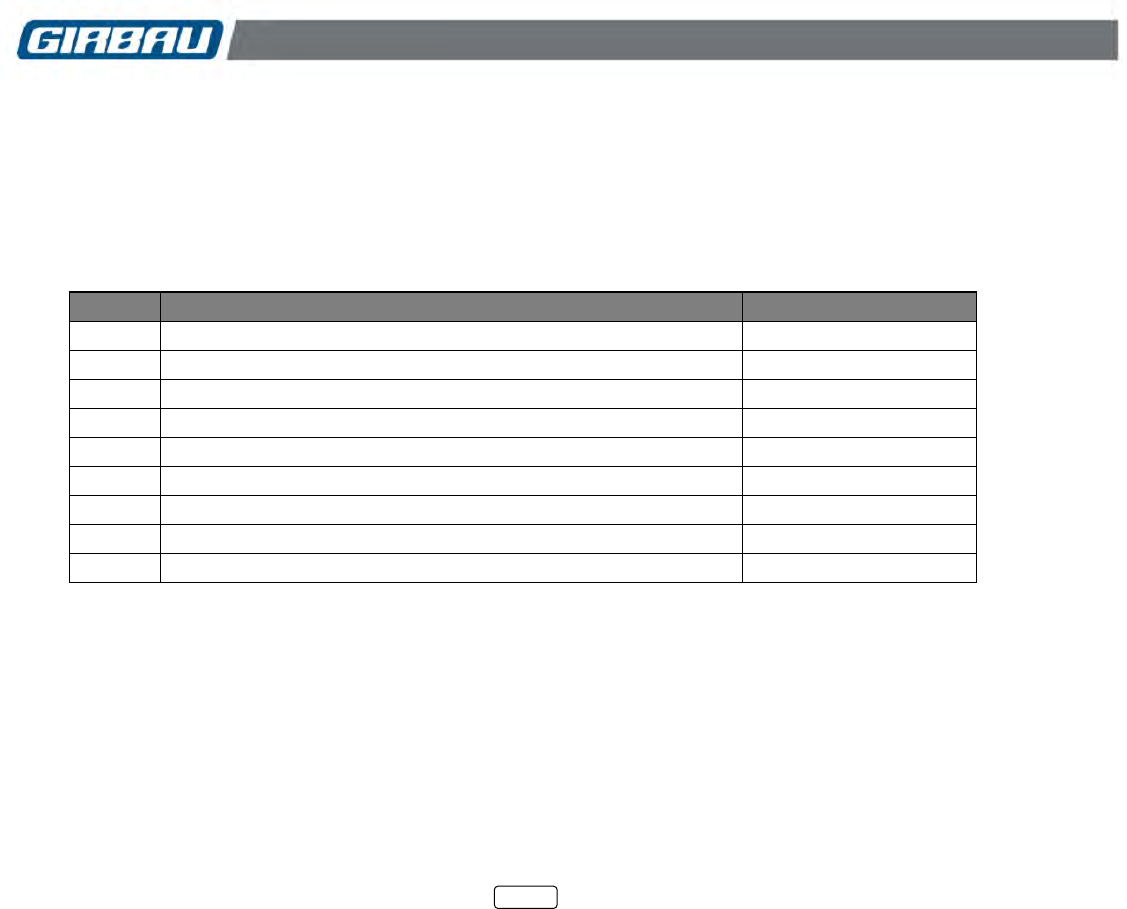

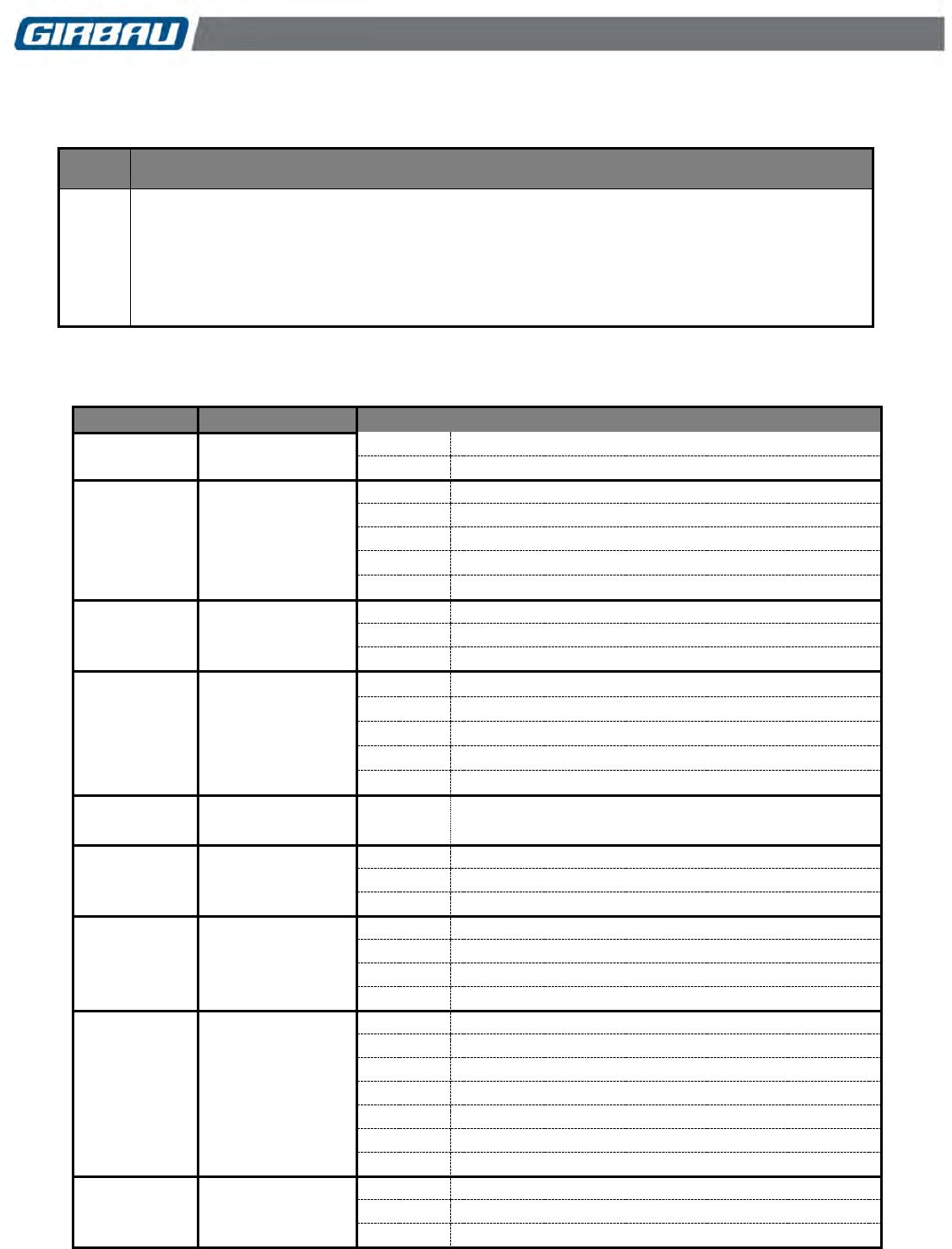

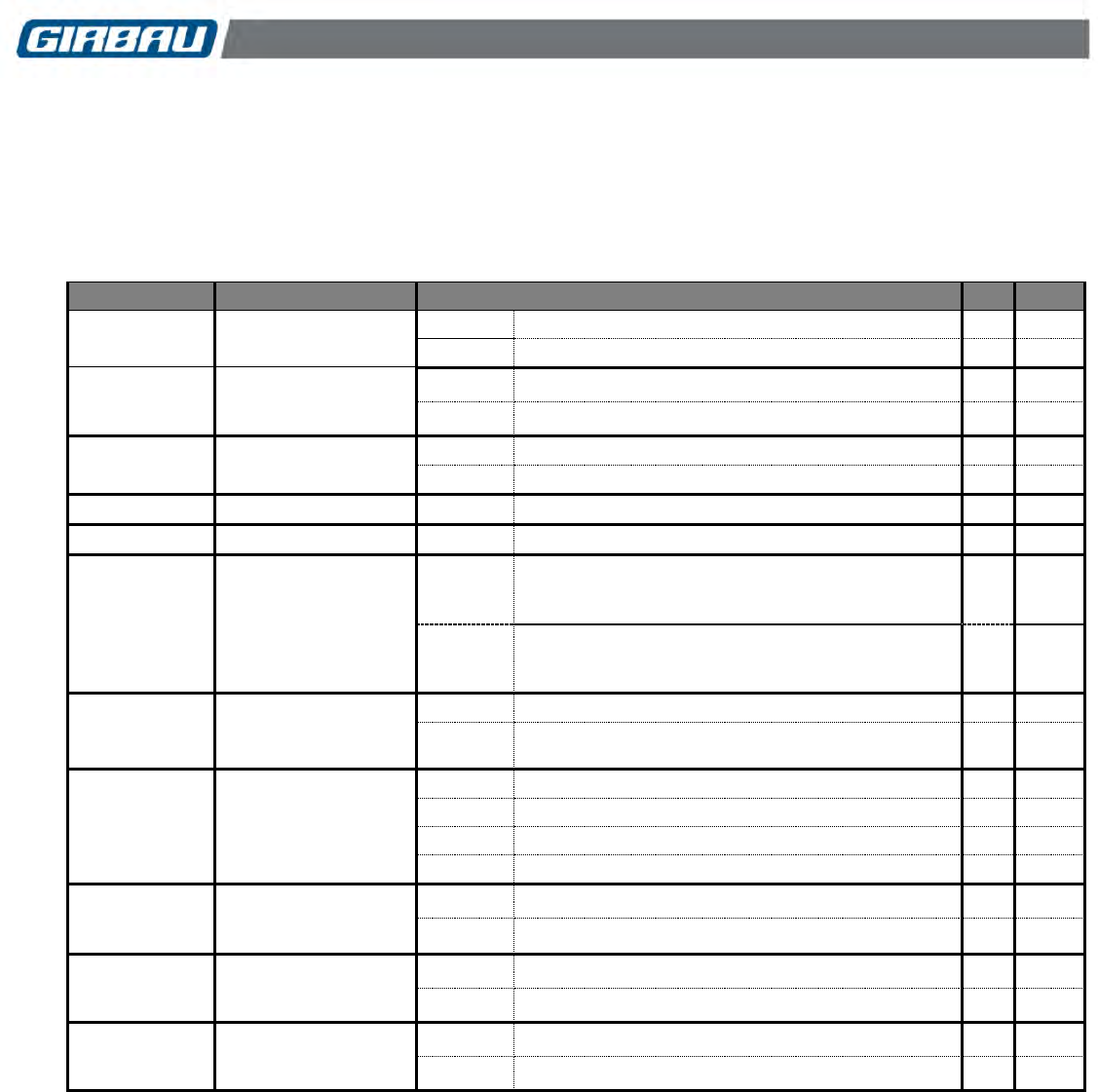

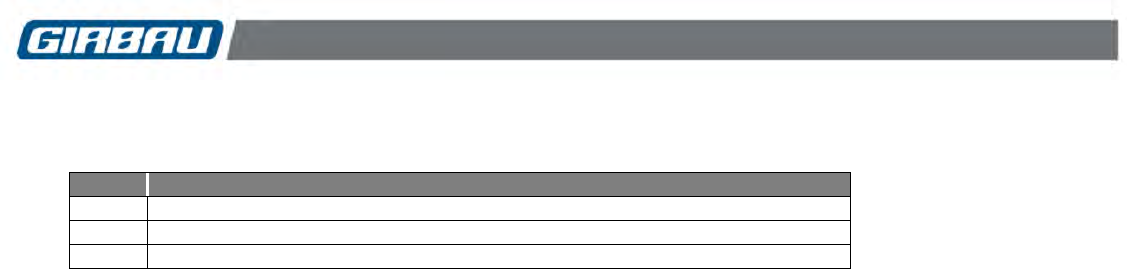

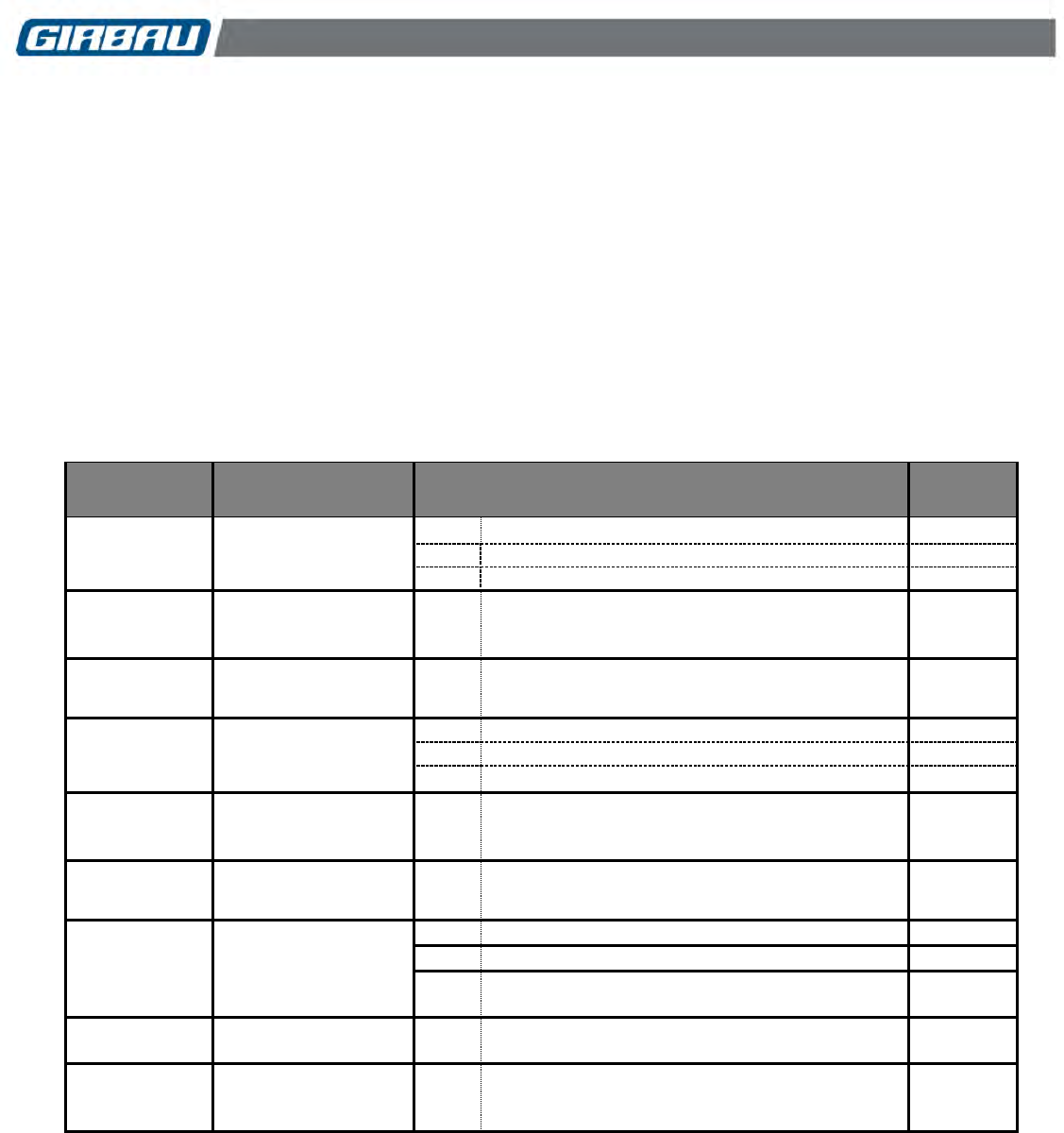

Models

High speed

From software

version

HS-6008

45

HS-6013

45

HS-6017

45

HS-6023

45

HS-6024

80

HS-6032

78

EH020

45

EH030

45

EH040

45

EH055

45

EH060

80

EH080

78

EH090

45

Models

Medium speed

From software

version

RMS610

45

RMS/RMG613

80

RMS/RMG617

80

RMS/RMG623

80

RMS/RMG628

80

REM025

45

REM/RMG033

80

REM/RMG040

80

REM/RMG055

80

REM/RMG070

80

Contents 3

Cod. 598144

Rev. 12/1218

CONTENTS ...................................................................................................................................................................... 3

SAFETY INSTRUCTIONS ................................................................................................................................. 5

1. INTRODUCTION AND APPLICATION .......................................................................................................... 9

2. DESCRIPTION ............................................................................................................................................... 9

2.1. Intended use of the washing machine .................................................................................................. 9

2.2. Construction characteristics .................................................................................................................. 9

2.3. Protection, safety and control elements .............................................................................................. 10

2.4. Safety functions ................................................................................................................................... 10

2.5. Characteristics of the control .............................................................................................................. 10

3. MODES OF USE .......................................................................................................................................... 11

4. PROGRAM EXECUTION MODE ................................................................................................................. 12

4.1. Control panel ....................................................................................................................................... 12

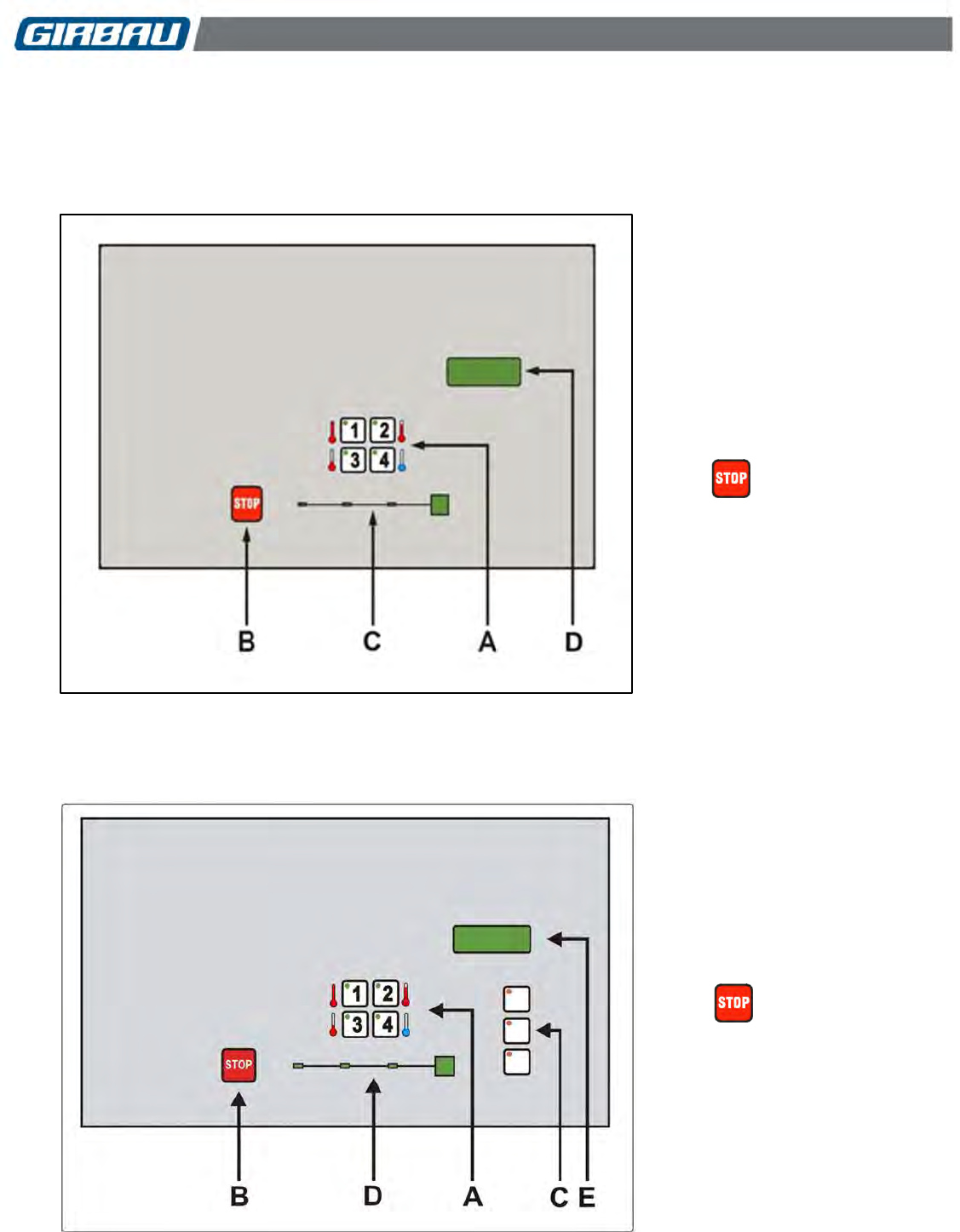

4.1.1. Machines with COIN CONTROL .................................................................................................. 12

4.1.2. Machines with PROFIT PLUS CONTROL ................................................................................... 12

4.2. Loading the washing machine ............................................................................................................ 13

4.3. Using the dispenser ............................................................................................................................ 14

4.4. Starting a program .............................................................................................................................. 16

4.4.1. Machines with COIN CONTROL .................................................................................................. 16

4.4.2. Machines with PROFIT PLUS CONTROL ................................................................................... 16

4.4.3. Door lock ...................................................................................................................................... 16

4.5. Program application and contents ...................................................................................................... 17

4.6. Unbalance control ............................................................................................................................... 18

4.7. Stop modes ......................................................................................................................................... 19

4.7.1. End of cycle and door opening ..................................................................................................... 19

4.7.2. Pressing the STOP key ................................................................................................................ 19

4.7.3. Interruption of the power supply ................................................................................................... 20

5. ADVANCED USE MODE ............................................................................................................................. 21

5.1. Access to the ADVANCED USE MODE ............................................................................................. 21

6. MODIFICATION OF THE PROGRAM CONTENTS. Menu Pro .................................................................. 21

6.1. Master program ................................................................................................................................... 22

6.2. Original content of the programs ......................................................................................................... 22

6.2.1. Program contents ......................................................................................................................... 22

6.2.2. Program contents. USA configuration .......................................................................................... 23

6.3. Definition of phases ............................................................................................................................. 24

6.4. Definition of programmable functions and values for each phase ...................................................... 24

6.5. Modifying a program ........................................................................................................................... 25

7. OPERATION MODE WITH PROGRAM ACCELERATOR. dEmo Menu ................................................... 29

8. INFORMATION MENU. InFO menu ............................................................................................................ 29

9. MODIFICATION OF OPERATING PARAMETERS. Mod menu ................................................................ 30

9.1. Parameters modification ..................................................................................................................... 30

10. MODIFICATION OF ACCESS CODE TO ADVANCED MODE. NCod menu .......................................... 34

11. PROGRAM PRICE. CASH Menu .............................................................................................................. 35

11.1. Single price for each program ........................................................................................................... 35

11.2. Programs price based on time bands ............................................................................................... 35

11.2.1. Hour Menu .................................................................................................................................. 36

11.2.2. CALE menu ................................................................................................................................ 36

11.2.3. CASH Menu ............................................................................................................................... 37

12. EXTRA OPTIONS MENU. EoPt menu ...................................................................................................... 39

13. TROUBLESHOOTING ............................................................................................................................... 41

13.1. Freeing a trapped person .................................................................................................................. 41

13.2. Manually releasing of the safety lock ................................................................................................ 41

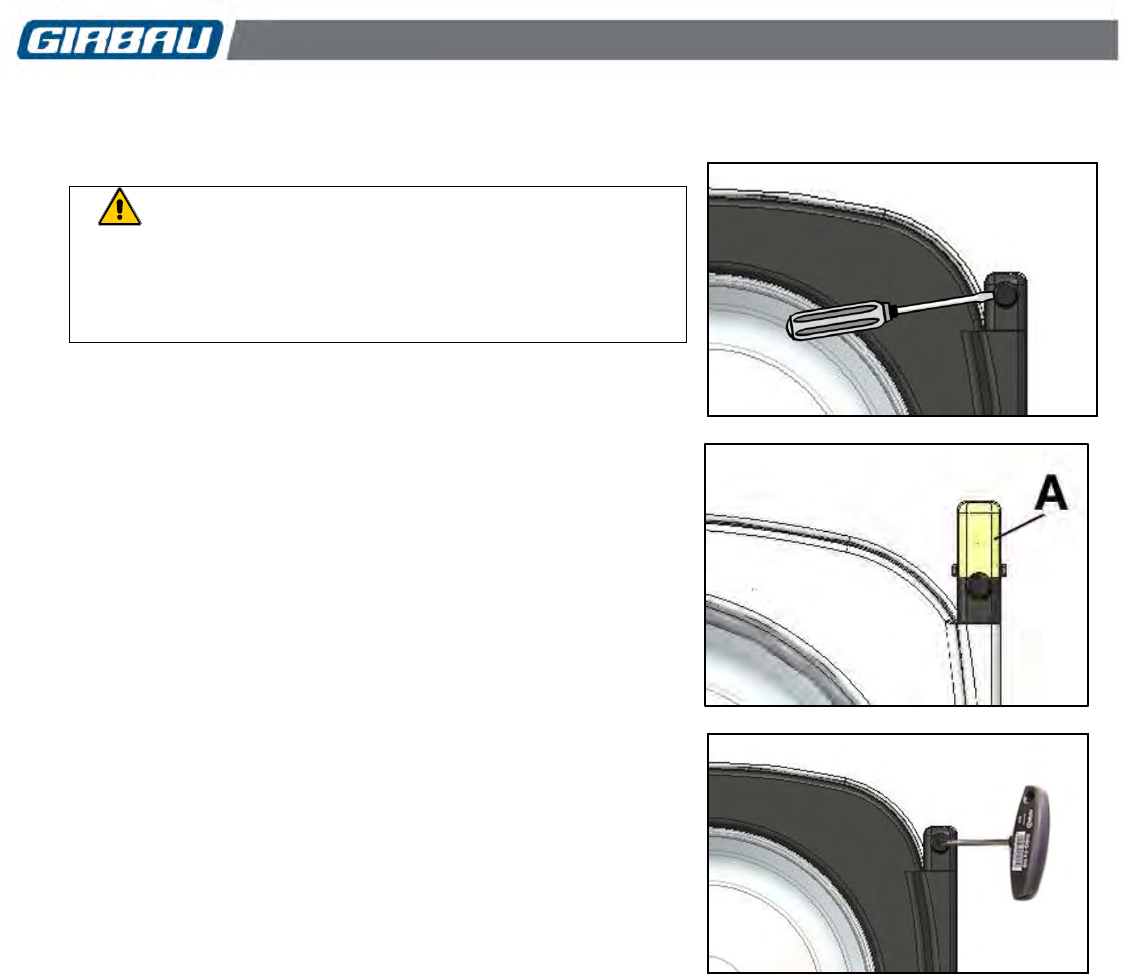

13.3. Disassembling the door of the washing machine ............................................................................. 42

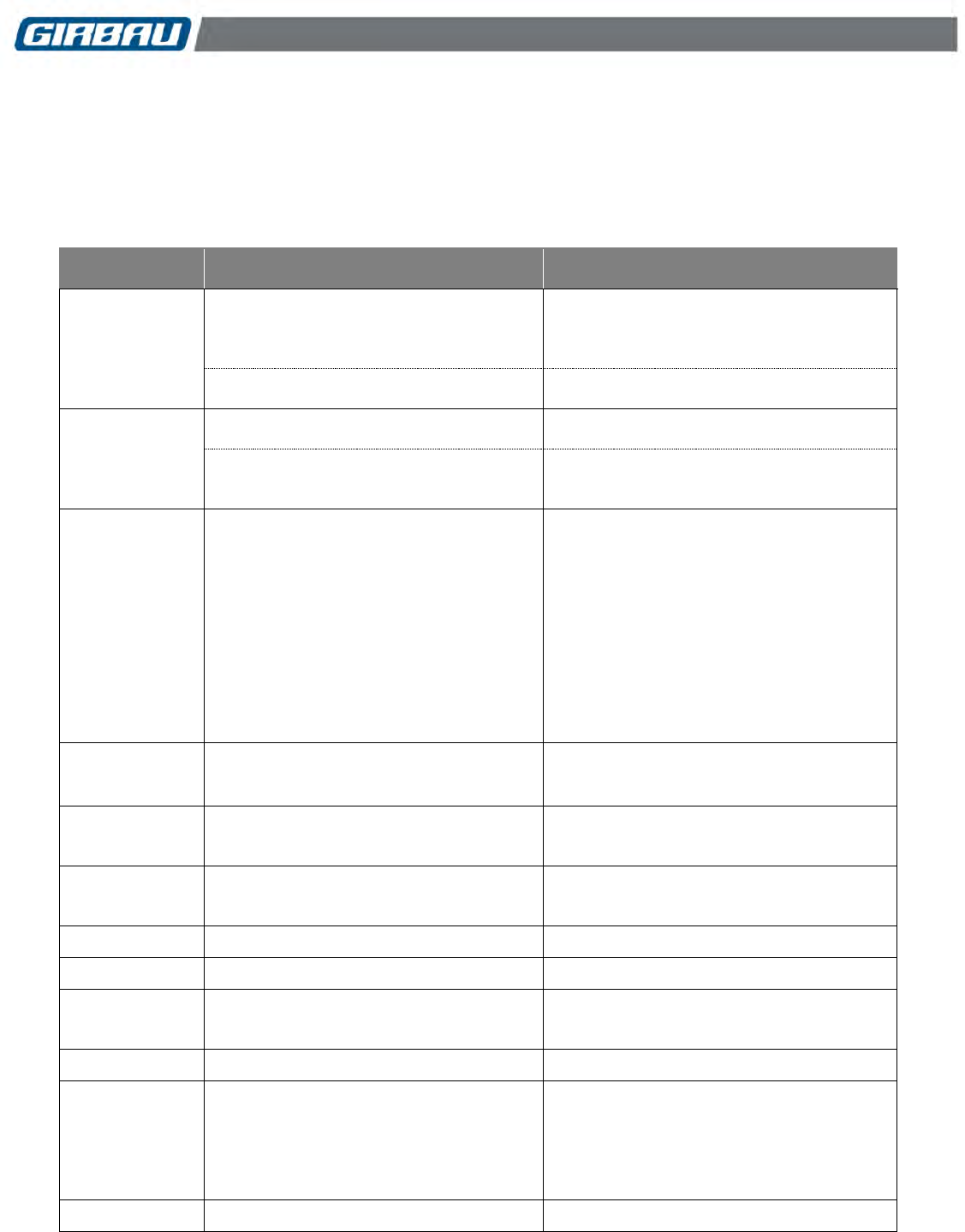

13.4. What to do when … ........................................................................................................................... 43

13.5. System alarms .................................................................................................................................. 44

Contents 4

Cod. 598144

Rev. 12/1218

14. MAINTENANCE ......................................................................................................................................... 45

14.1. Cleaning the washer ......................................................................................................................... 45

14.2. Cleaning the door seal ...................................................................................................................... 45

14.3. Cleaning the solenoid valve filters .................................................................................................... 46

14.4. Checking safety mechanisms ........................................................................................................... 46

14.4.1. Checking the door lock ............................................................................................................... 46

14.4.2. Verify the general Emergency Stop of the laundry .................................................................... 47

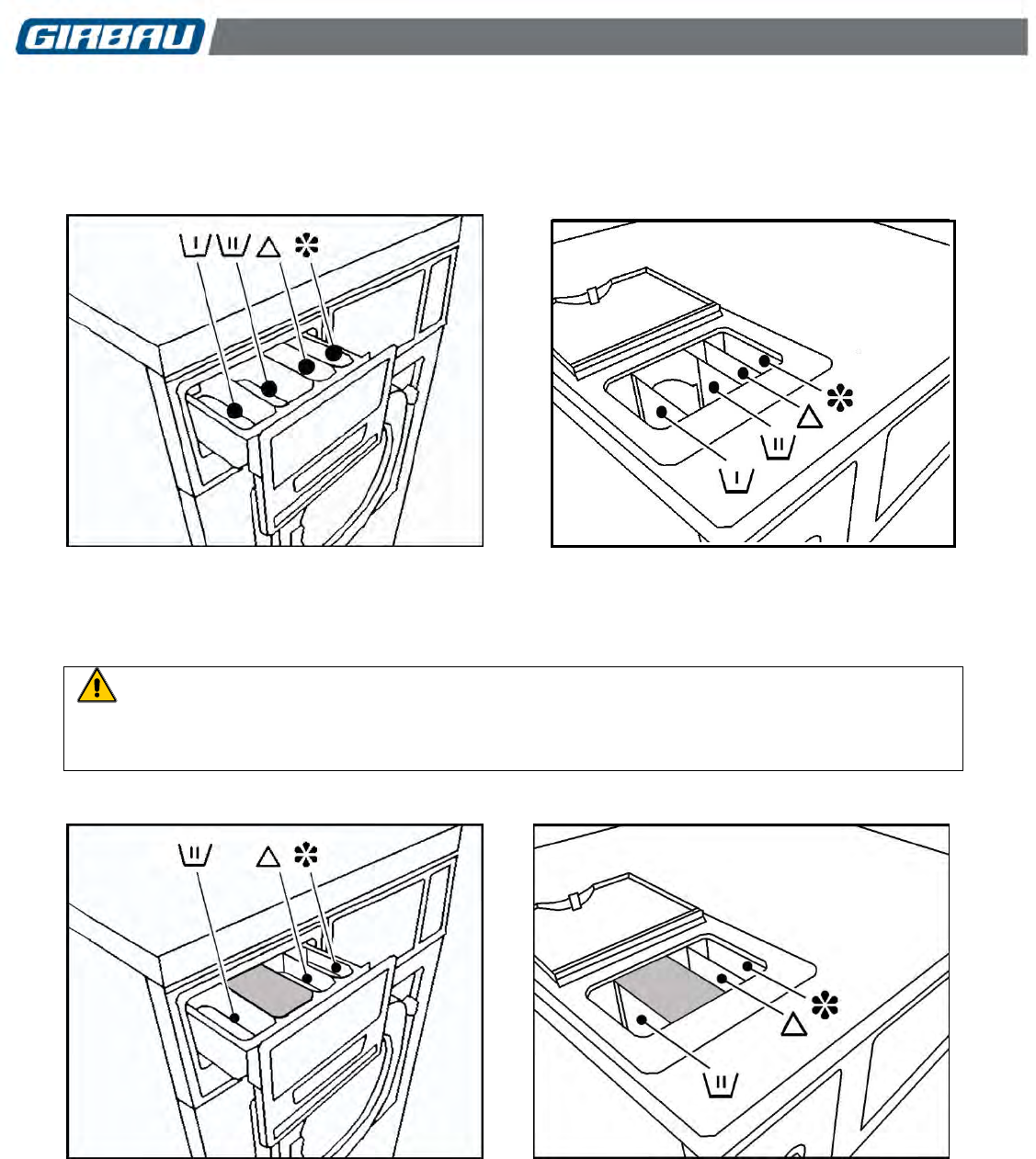

14.5. Cleaning the dispenser ..................................................................................................................... 48

14.5.1. Washers with front dispenser ..................................................................................................... 48

14.5.2. Washers with top dispenser ....................................................................................................... 48

14.6. Cleaning the drain pump ................................................................................................................... 49

14.7. Checking the condition of the bearing housing seals ....................................................................... 49

14.8. General Overhaul .............................................................................................................................. 49

15. WITHDRAWING FROM SERVICE ............................................................................................................ 50

Safety instructions 5

Cod. 598144

Rev. 12/1218

WARNING!

IMPORTANT SAFETY INSTRUCTIONS

WARNING: To reduce the risk of fire, electric shock or injury to persons when using the machine, follow basic

precautions, including the following:

1. READ all instructions before using the machine, and KEEP them in a prominent location for customer use.

2. Do not wash articles that have been previously cleaned in, washed in, soaked in, or spotted with gasoline,

dry cleaning solvents, and other flammable or explosive substances as they GIVE OFF VAPOURS that

could ignite or explode.

3. DO NOT ADD petrol, dry-cleaning solvents, or other flammable or explosive substances to the wash water.

These substances give off vapours that could ignite or explode.

4. Under certain conditions, hydrogen gas may be produced in a hot water system that has not been used for

two weeks or more. HYDROGEN GAS IS EXPLOSIVE. If the hot water system has not been used for such

a period, before using the washing machine, turn on all hot water faucets and let the water flow from each

for several minutes. This will release any accumulated hydrogen gas. As the gas is flammable, do not

smoke or use an open flame during this time.

5. Do not allow children to play on or in the washer. CLOSE SUPERVISION of children is necessary when the

washer is used near children.

6. Before the washer is removed from service or discarded, REMOVE the door.

7. DO NOT TRY TO OPEN THE WASHER’S DOOR if the drum is moving.

8. Do not install or store the washer where it will be exposed to the WEATHER.

9. DO NOT TAMPER with controls.

10. DO NOT REPAIR OR REPLACE any part of the washer or attempt any servicing, unless this is specifically

recommended in the user instructions or in published user-repair instructions that you understand and have

the skills to carry out.

11. DO NOT REMOVE any safety device OR MODIFY OR MANIPULATE any component or part of the

machine. DO NOT INSTALL any extra elements inside the machine.

12. Any part of the machine that is replaced may affect its operation and the user’s safety. For this reason,

USE ONLY THE MANUFACTURER’S ORIGINAL SPARE PARTS. Failure to comply with this warning can

cause serious accidents, malfunctions and the loss of the machine’s guarantee and certifications.

13. Failure to comply with or observe the legislation and regulations covering health, safety and prevention of

risks in the workplace applicable in the country where the machine has been installed, or actions contrary

to common sense, MAY CAUSE personal injury or even death to the user.

14. The machine should only be used for those purposes established by the manufacturer and following the

instructions for use set out in the instruction manuals. Any use not specified in the manuals may lead to

additional risks. Pay special attention to information headed DANGER, WARNING and PRECAUTION.

15. The room where the machine is located MUST comply with the environmental conditions (air venting,

temperature, humidity, etc.) specified in the technical specifications table. NEVER INSTALL THE

MACHINE IN ENVIRONMENTS where it will be splashed with water or where there is a very high level of

humidity in the atmosphere.

16. Clearly mark out danger areas and PREVENT public access to them when the machine is operating. Do

not expose yourself to drainage areas or to vapour, condensation, combustion gas or ventilation outlets.

17. All machines working at temperatures present a fire risk. Take EXTREME care: CLEAN the machine of

inflammable materials: lint, fluff, soot, etc. on a regular basis. KEEP the environment free of combustible

materials and PLACE suitable extinguishers near the machine in easily accessible places.

Safety instructions 6

Cod. 598144

Rev. 12/1218

18. All installations required for the proper operation of the machine MUST be carried out by a duly accredited

Registered Installation Contractors (see Note 3), in compliance with the legal regulations applicable in the

country of use.

19. The machine MUST be commissioned by the Authorised Technical Service in the presence of the

Customer Technical Service (see Notes 2 and 4) or a responsible person appointed by the customer.

20. This machine MUST BE USED by personnel who are properly trained in how to use it (see Note 1).

21. NEVER START THE MACHINE, OR USE IT, IF THE FOLLOWING ARE ABSENT, INCORRECTLY

POSITIONED OR MALFUNCTIONING:

COVERS (GUARDS) AND PROTECTIVE DEVICES

SAFETY DEVICES

CONTROL ELEMENTS

22. DO NOT USE the machine if you notice any abnormal noise or smell or if you suspect that the machine is

faulty or defective.

23. The inspections required by the regulations applicable to the country where the machine is being used

must be carried out. It is advisable to request an overall, detailed service of the machine by the Authorised

Technical Service every year (see Note 2).

24. WARNING!

INSPECTION, MAINTENANCE OR REPAIR OPERATIONS

Before carrying out any action on the machine:

Close and mechanically lock the manual fluid supply valves.

Check that the bath has COMPLETELY drained, that no part of the machine is at a high temperature

and that no circuits or containers are under pressure.

Check that all the machine’s moving parts are halted or in their rest position. Securely fix all the

machine’s moving parts that could cause an accident.

To reduce the risk of electric shock:

COMPLETELY disconnect the machine from the mains power supply and take steps to prevent

accidental reconnection. TURNING OFF THE ON SWITCH OR PRESSING THE STOP KEY IS NOT

ENOUGH.

Disconnect the electrical connection of any circuit external to the machine; for example external dosing

equipment, central vending units, linen feeders or folders, etc. The electrical connection for these circuits

is independent of the machine’s electrical connection.

To prevent the risk of electrical discharge caused by residual voltage, wait at least five minutes before

removing any guard or cover from the machine.

Failure to follow these warnings may cause a serious accident.

25. CONTACT the Installation Contractors or the Authorised Technical Service (see Notes 3 and 2) in the

event of any doubt, anomaly or problem.

26. It is advisable to copy and enlarge the SAFETY INSTRUCTIONS and place them in a visible place in the

laundry.

27. THE MANUFACTURER ACCEPTS NO RESPONSIBILITY IF THESE SAFETY INSTRUCTIONS AND

ALL THE INFORMATION IN THE CORRESPONDING MANUALS ARE NOT FOLLOWED.

SAVE THIS INSTRUCTIONS.

Safety instructions 7

Cod. 598144

Rev. 12/1218

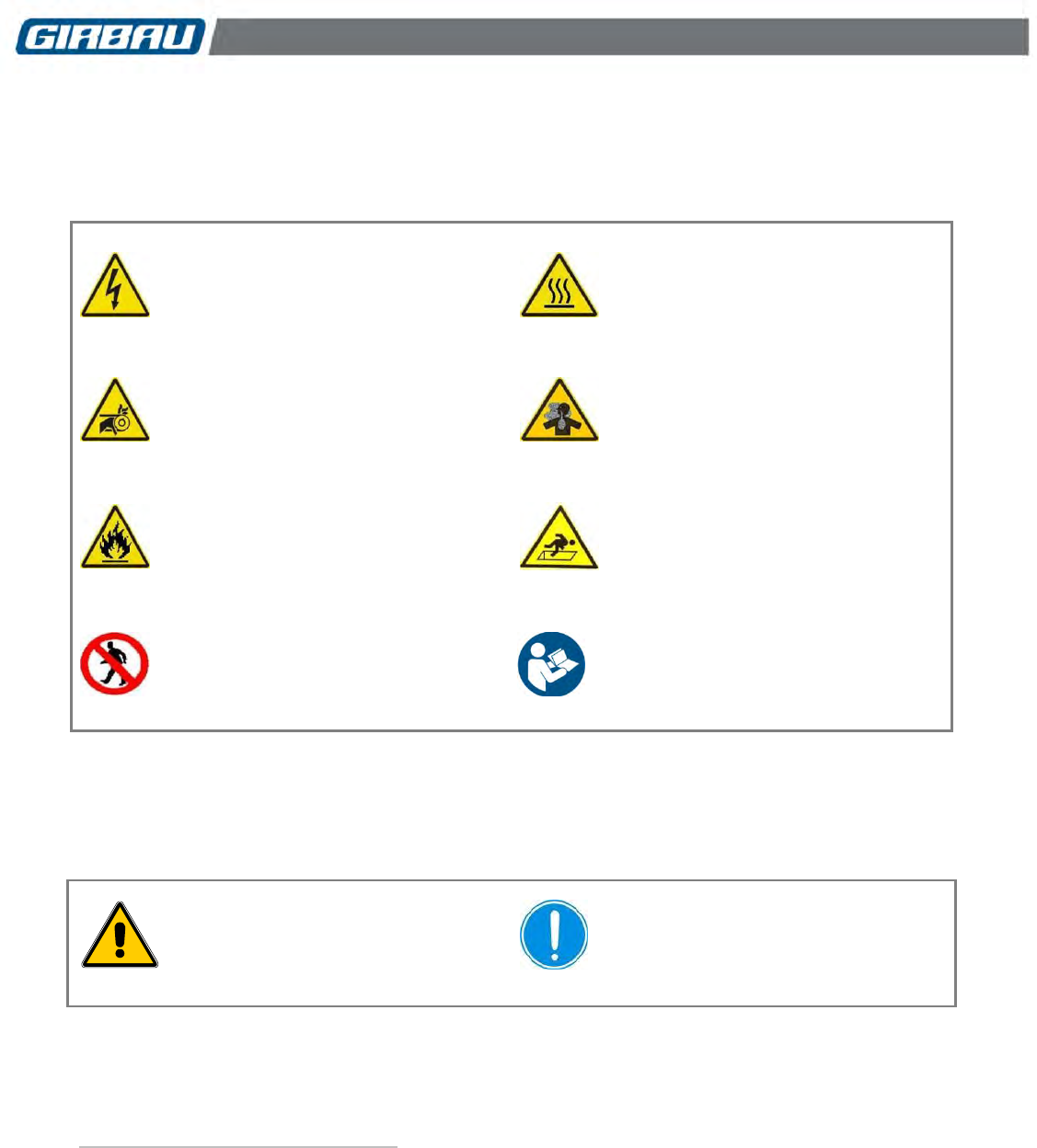

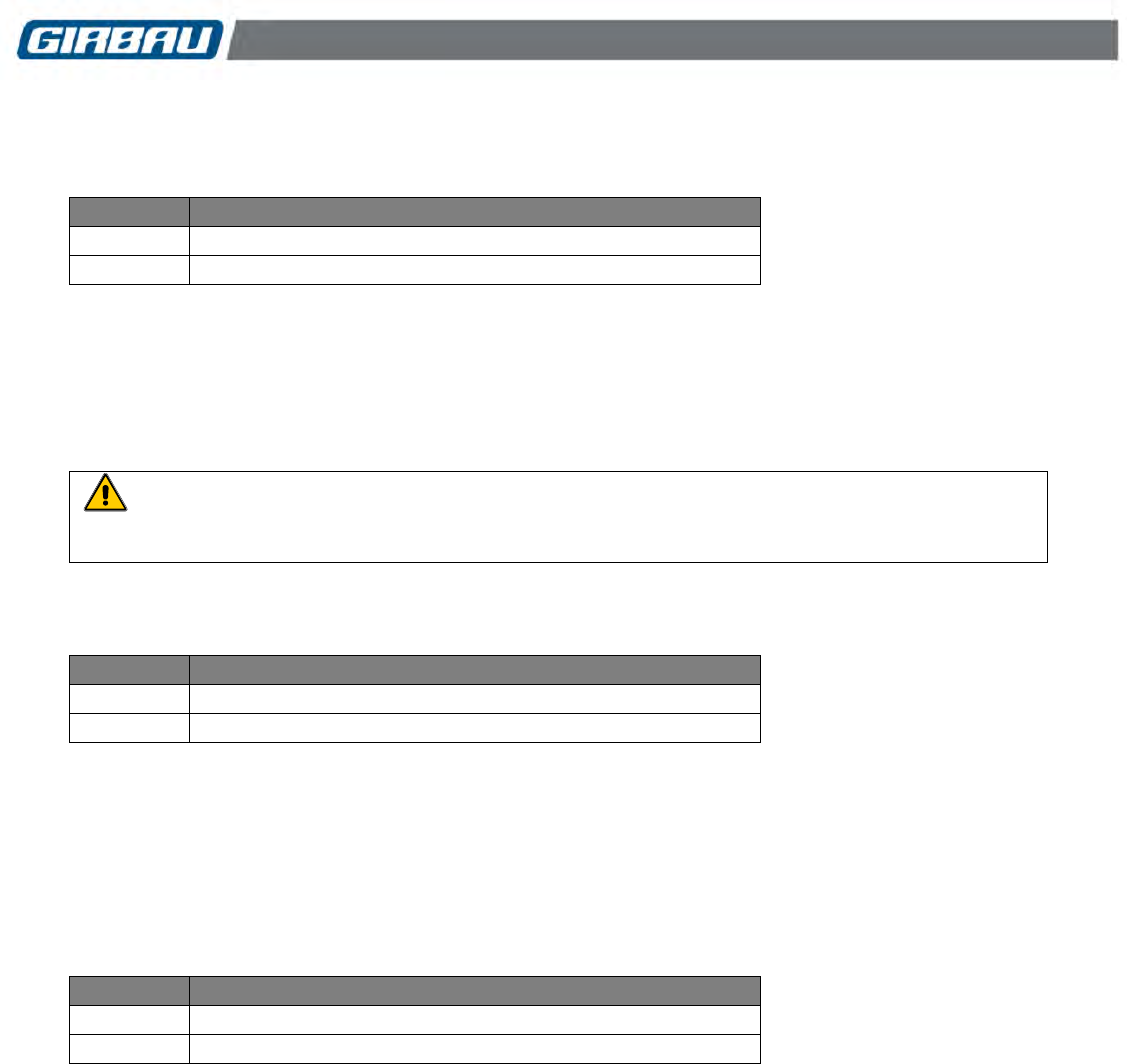

SYMBOLS USED IN MACHINE LABELLING

Electrical risk

Protective guard for elements carrying

an electric current.

High temperature risk

Handle with caution.

Use adequate protection.

Mechanical risk

Protective guard for moving parts.

Risk of inhaling harmful or irritant

vapours

Keep the doors/covers closed.

Use adequate protection.

Flame risk (only on some machines)

Protective guard for flame.

Risk of falling

Use proper access and safety methods.

Access prohibited

Refer to instruction manual/booklet

SYMBOLS USED IN THIS MANUAL

Symbol used to highlight a possible

HAZARD, WARNING or NOTE.

This symbol is used to emphasise a

particular explanation.

TRANSLATION OF THE ORIGINAL MANUAL

NOTES:

(1) Trained personnel refers to those who have read and understood the Instruction Manual, who have been trained by the Authorised

Technical Service or by a representative of the customer present at the start-up who is familiar with the operation of the machine and is

authorised to use it.

(2) Authorised Technical Service (ATS) is one that has been recognised under contract and properly trained by the manufacturer.

(3) Registered Installation Contractors are those officially approved by the government of the country the machine is to be installed.

(4) Customer Technical Service (CTS) is one that has been authorised by the customer and which has sufficient basic technical knowledge

to correctly interpret and carry out the actions attributed to it in this manual. The manufacturer strongly recommends that the customer

should have its own technical service, particularly in laundries with large-scale machinery installations.

Safety instructions 8

Cod. 598144

Rev. 12/1218

IMPORTANT INSTRUCTIONS FOR USE AND PRESERVATION

1. INTENDED USE OF THE MACHINE AND INAPPROPRIATE USE. This machine is designed and intended

solely for processing fabrics washed in a water bath or that have been previously treated in these

conditions. Any use other than this is contraindicated without written authorisation from the manufacturer.

2. Maximum output, performance, reliability and durability are achieved when the machine is installed, used

and maintained correctly, and if a comprehensive and detailed service is carried out annually by the

Authorised Technical Service.

3. The machine’s MATERIALS that are in direct contact with the chemical products involved in treating the

linen are detailed in the manual.

4. The user must consult the supplier of the chemical products USED THROUGHOUT THE WHOLE LINEN

TREATMENT PROCESS regarding the risks associated with its products and their combination. It must be

confirmed that the products are not flammable, ARE MUTUALLY COMPATIBLE, and that they will not

cause oxidisation or deterioration of the machine or any injury to the people using them.

It should be borne in mind that in certain conditions of use, hypochlorite (bleach) can generate chlorine gas.

Chlorine is a corrosive and oxidising substance which, at high concentrations and temperature, deteriorates

stainless steel and elastomers.

There are other highly oxidising agents, such as the ozone, that can have the same effect.

5. FOLLOW the treatment recommendations for each fabric indicated by its manufacturer. THE

MANUFACTURER OF THE MACHINE accepts no responsibility for damage caused by inappropriate

treatment of a fabric.

6. Periodically CLEAN the outside of the machine to prevent damage to its metal parts. This will improve

safety and extend its life. To clean the machine, use water and detergent. Rinse with a damp cloth and

then dry off. To remove accumulated lint, use a suitable vacuum cleaner. Cleaning with water jets or

pressurised steam is prohibited.

7. NEVER use harsh products to clean the machine and laundry room. Some products on the market give off

highly corrosive gases.

8. If machine is left idle for long periods of time, it must be PROTECTED from humidity and temperature

variations.

9. Faults arising from improper machine operation may VOID THE WARRANTY.

10. When asking for information on your machine, MENTION the model and serial number. This information

can be found on the specification nameplate incorporated into the machine.

With every machine, the manufacturer provides all the necessary technical information and documents required

for its use. KEEP IT IN GOOD CONDITION.

Description 9

Cod. 598144

Rev. 12/1218

1. INTRODUCTION AND APPLICATION

This manual contains the OPERATION and ADVANCED USE MODE instructions for washing machines with

COIN CONTROL system with or without extra options.

Application

This manual applies to the following models:

HS, EH, RMS610, REM025 models with software version 31 or higher

RMS, RMG and REM models with software version 65 or higher

2. DESCRIPTION

Washer extractor designed to wash or treat fabric in a water bath.

Control designed primarily for use in coin-op laundries.

2.1. Intended use of the washing machine

This machine has been made and designed for washing or treating textile materials in a water bath. These textile

materials must be free of flammable or explosive products. Unless approved by the manufacturer in writing, it is

not considered appropriate for any other use.

Under-loading as well as overloading is not recommended. Always endeavour to match the capacity of the

machine.

It is not advisable to insert bags full of laundry. Where necessary, load the machine up to its set limit.

It is not recommended to spin carpeting, canvas or waterproof fabrics.

2.2. Construction characteristics

HIGH SPEED MODELS (HS / EH). Washing machines capable of spinning at a speed higher than 350G

(280G in model HS-6008/EH020) and up to 400G without needing to be bolted down. The design of its

suspension system cushions up to 95% of the vibrations produced during the spin cycle.

MEDIUM SPEED MODELS (RMS/REM/RMG). Hard-mount construction. They have to be bolted down to

the floor.

- Approximate spin speed: 125G, 150G, on models RMS, REM.

- Spin speed: 200G on models RMG.

Stainless steel inner and outer drum. The openings in the drum blades promote the uniform distribution of

bath water and improve the yield of the washer both during the wash and the rinse cycles.

The drum rotation is produced by an asynchronous AC motor controlled by an inverter.

The hot and cold water connections have a safety mechanism to prevent contaminating by back-flowing

into the general drinking water system.

Large capacity drain valve. (Option for pump drainage in models HS-6008/EH020).

Water inlets and all product dispensers made using a common collector with an anti-siphon mechanism.

Option for heating the bath using electric heaters or steam injection.

Description 10

Cod. 598144

Rev. 12/1218

2.3. Protection, safety and control elements

Fixed guards: Covers. These prevent access to dangerous points or moving parts. Protect from accidental

machine spattering.

Moving guards:

- Dispenser cover.

- Door with interlock microswitch, door lock and delayed opening.

Overflow. When the bath level is exceeded duet to solenoid valve failure, the bath is drained through the

drain outlet.

Thermal fuse to protect the electric heaters.

Electric circuit safety measures: To protect the electric circuit against external malfunctions and prevent

any malfunctioning from causing harm to the operator.

Sound alarm: Among other functions, the acoustic signal warns of possible alarms.

Unbalance microswitch. (Only in high speed models). Additional electromechanical safety to protect

against unbalance of drum load during the spin cycle.

2.4. Safety functions

Bath level control. Allows selecting different bath levels during the wash cycle and controls the overflow

safety and minim level of connection to the heating system and door opening.

Temperature control. Allows selecting the bath temperature during the wash cycle and controls the bath

insufficient temperature and overheat safeties.

Unbalance control. Repositioning of the washer's load if the inverter power control detects unbalance.

Door opening safety. Allows the opening of the door in safety conditions.

Safety measures against entrapment. To reduce the risk of a child becoming trapped inside a washing

machine while playing, or to help in freeing them during the first moments of launching a program, the

running sequence of a wash cycle is as follows:

After giving the start order, a 30-second safety time is started during which the drum rotation and the water

inlet operate at short impulses and door remains released. Further information in Sections: Freeing a trapped

person (Chapter 9) and Stopping methods (Chapter 4).

2.5. Characteristics of the control

Operation of the washer controlled by microprocessor.

Operation of the washer adaptable to the possibilities of the installation and the needs of the user. Designed

primarily for use in coin-op laundries.

Great versatility in individually modifying the content of each program. Further information in specific sections

of the ADVANCED USE MODE.

Temperature control in the wash phase achieved by the hot and cold water mixer in accordance with the

programmed temperature and the activation of the heating system. Precision of +/- 2 ºC (+/- 3.5 ºF).

Level control achieved using an electronic pressure transmitter.

Series communication between the washer microprocessor and the inverter’s control of the motor.

Multiple controls that assure the safe use of the washer.

Washing programs: availability of 4 pre-programmed programs. Each program allows for: pre-wash, wash

with a maximum temperature of 80 ºC and four rinse phases with a final spin at high speed.

The programs are activated by the introduction of coins or tokens into the washing machine’s meter o by a

signal from the central vending point.

Programming programs price. Option for automatically changing the prices for each program depending on

time period and day of the week.

Executed individual program counters.

Modes of use 11

Cod. 598144

Rev. 12/1218

3. MODES OF USE

The COIN CONTROL has TWO MODES OF USE.

PROGRAM EXECUTION MODE

This mode groups together the functions or actions aimed at selecting and executing the different wash

programs.

Information regarding this intervention mode: chapter 4 of this manual.

ADVANCED USE MODE

Covers the functions or interventions aimed at:

Modifying or displaying the content of the washing programs.

Consult the software version for the washer and the contents of the different program meters.

Modifying the general operating parameters.

Modifying the access code for ADVANCED USE MODE.

Setting the time of the system clock (optional).

Managing programs price.

Information regarding this intervention mode: From Chapter 5.

Program execution mode 12

Cod. 598144

Rev. 12/1218

4. PROGRAM EXECUTION MODE

4.1. Control panel

4.1.1. Machines with COIN CONTROL

Fig. 4.1

KEYS

A: Washing program selection

keys.

Each key corresponds to a

program. The selection of a

program is indicated by the

LED associated with the key.

B: The key: Program stop.

INDICATOR LIGHTS for a

program’s start sequence:

C: Phase of the program in

progress

D: Display

4.1.2. Machines with PROFIT PLUS CONTROL

Fig. 4.2

KEYS

A: Washing program selection

keys.

Each key corresponds to a

program. The selection of a

program is registered by the LED

associated to the key.

B: The key: Program stop.

C: Keys for selecting the extra

options

INDICATOR LIGHTS for a

program’s start sequence:

D: Phase of the program in

progress

E: Display

Program execution mode 13

Cod. 598144

Rev. 12/1218

SPECIFIC KEYBOARD FOR KOREA

The washing machines for Korea have a keyboard with the following special features:

COIN CONTROL keyboard:

The 1, 2 and 4 keys are coloured black.

The C, D and F LEDs and the LEDs associated with the 1, 2, 3 and 4 keys are not visible.

PROFIT PLUS CONTROL keyboard:

The 1, 2, 3 and 4 keys are coloured black.

The C, D and F LEDs and the LEDs associated with the 1, 2, 3 and 4 keys are not visible.

MAIN REPORTS that appear on the display:

REPORT

MEANING

door

Washer with door open. Machine ready to start a program

SEL

Indicates program selection

Pr-*

Program selected

C** / F***

Bath temperature (machines with heating)

8888

Program price

Minutes remaining in the program

End

End of program. Door unlocked. Machine in idle mode

4.2. Loading the washing machine

Group the fabrics to be washed into homogeneous loads, attempting wherever possible to reach the nominal

value of the load.

Empty all pockets, fasten buttons, close zippers and remove accessories that are not machine-washable.

Mixing whites with other colours is not recommended.

Open the door and load the machine. The LED of washer loading and program selection blinks.

Washer load recommendations according to the type of fabric to be washed:

Cotton fabrics: nominal load

Synthetic fabrics: between 80% & 90% of nominal load

Delicate fabrics: between 35% & 50% of nominal load

Do not overload the machine; the door must be able to close easily.

Whilst the door is open, the display reads door, indicating that the door must be closed in order for the program

to begin.

Health and safety instructions for loading and unloading the washer

Installing washing machines on raised bases, in accordance with the instructions set out in the corresponding

installation manuals, aids in loading and unloading the machine by avoiding the need to adopt awkward

positions.

Use linen collecting and transporting containers that are of a suitable height for the washer size. Consult the

dimensions of the washers set out in the corresponding installation manual.

Take care not to overload the machine. Overloading the washer leads to excessive strain when processing the

linen.

Certain chemical products that are used in the washing process are toxic. Handle them with care and wear

appropriate protection.

Follow the legislation and regulations for Health and Safety in the Workplace in force in the country where the

machine has been installed.

Program execution mode 14

Cod. 598144

Rev. 12/1218

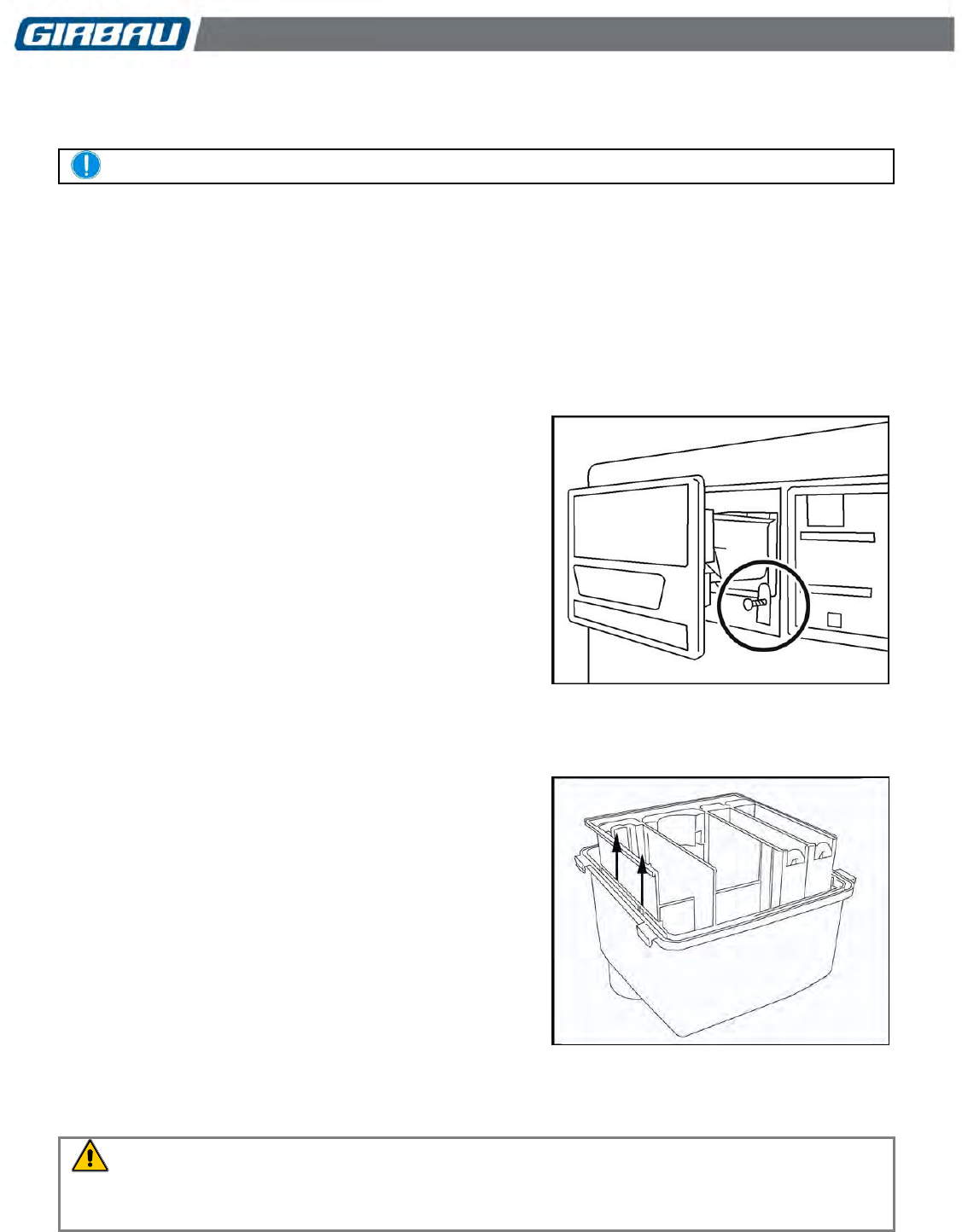

4.3. Using the dispenser

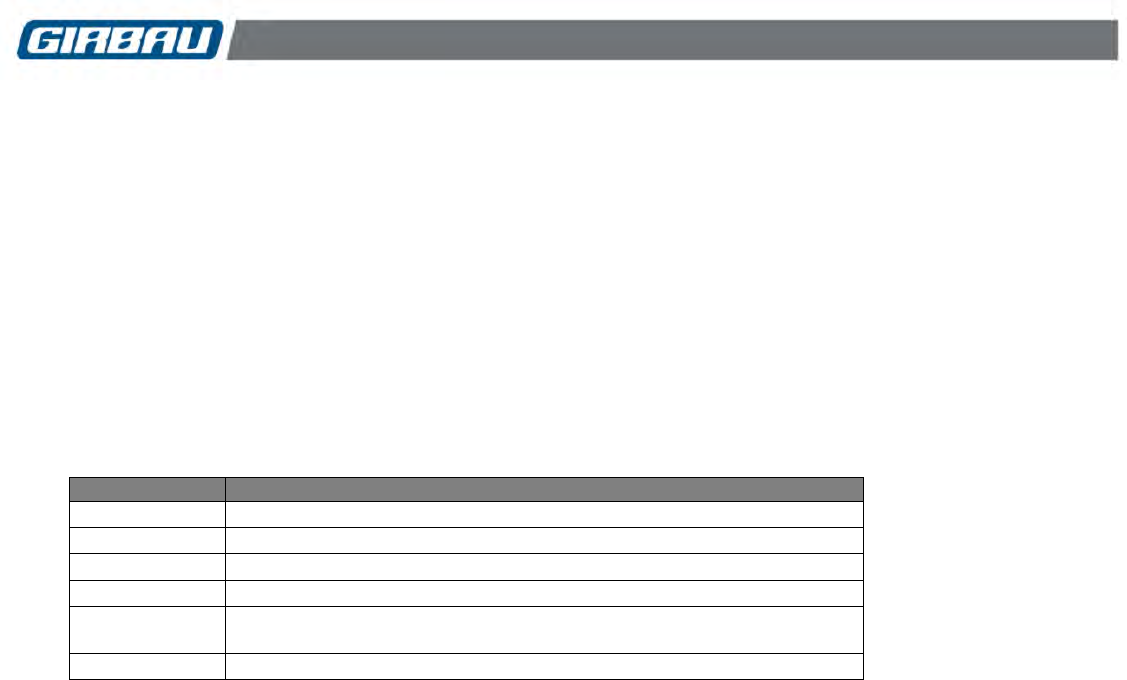

HS, RMS and RMG models

Fig. 4.3 Fig. 4.4

Washing machines models EH, REM, RMG (USA/CANADA)

WASHING MACHINES WITHOUT PRE-WASH PHASE

To avoid clogging the dispenser, products are prevented from being added in the unused

compartments (Fig. 4.5 and 4.6). It is important to warn the operator about the correct use of the

dispenser.

Fig.4.5 Fig.4.6

Program execution mode 15

Cod. 598144

Rev. 12/1218

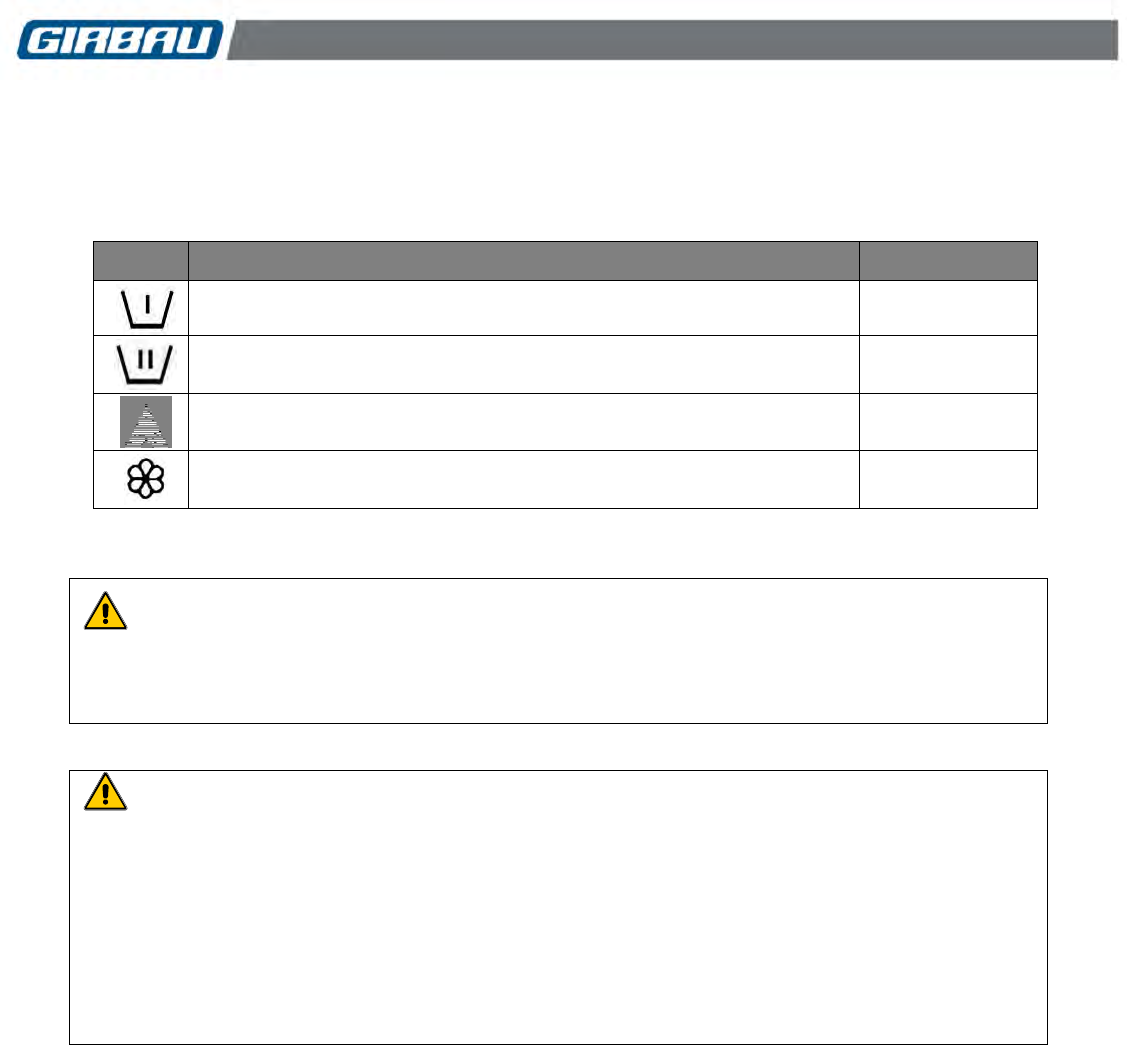

Fill the compartments with the corresponding products, according to these symbols.

Symbols used in the dispenser (Fig. 4.2, 4.3, 4.4 and 4.5)

FUNCTION

PROGRAMMING

Powdered detergent. Normally used in the pre-wash phase

d1

Powdered detergent. Normally used in the wash phase

d2

Liquid product. Normally used for bleaching (chloride, bleach, etc.)

d3

Liquid product. Normally used as a softener/neutraliser

d4

IN ORDER TO OPERATE CORRECTLY AND TO PREVENT POSSIBLE DAMAGE AND SPLASHING,

THE DISPENSER DRAWER MUST ALWAYS REMAIN CLOSED, EXCEPT WHEN ADDING

PRODUCTS.

SUDS CONTROL

The mechanical action of front-loading washing machines improves the quality of the wash but

encourages the creation of suds.

Remember that a suds bath always reduces the efficiency of your wash. ALWAYS USE

CONTROLLED SUDS DETERGENT.

Oversudsing causes an increase in the pressure inside the machine and decreases the efficiency of

the sealing systems.

Repeated washing with a large amount of suds considerably reduces the life of seals and bearings.

THIS CIRCUMSTANCE IS NOT COVERED BY THE MACHINE’S WARRANTY.

Program execution mode 16

Cod. 598144

Rev. 12/1218

4.4. Starting a program

4.4.1. Machines with COIN CONTROL

Close the door of the washing machine. SEL report displayed.

Place the washing products in the dispenser and close it (refer to section 4.3).

Select the desired program by pressing the corresponding keys. (For information on the characteristics of

each program, refer to section 4.5: Wash Programs). The selected program will be shown on the display.

The LED associated with the selected program key will light up.

The price for the program or the number of tokens to be inserted will be displayed, and the LED will light up,

indicating that the payment must be made for the program.

Insert the coins or tokens requested. The display will show the price or the number of tokens left to start the

selected program.

It is possible to change the selected programme while inserting the coins or tokens. The price of the

program adapts according to the new selection and the value of the coins or the number of tokens

introduced will remain in the memory. The newly selected program will be displayed on the LED relating to

the key.

Once all the coins or tokens have been inserted, the selected wash program will start.

4.4.2. Machines with PROFIT PLUS CONTROL

Close the door of the washing machine. SEL report displayed.

Place the washing products in the dispenser and close it (refer to section 4.3).

Select the desired program by pressing the corresponding keys. (For information on the characteristics of

each program, refer to section 4.5: Wash Programs). The selected program will be shown on the display.

The LED associated with the key for the program selected will light up, and the price for the program or the

number of tokens to be inserted will be displayed.

Select the extra options you want by pressing the corresponding key. The LED for the option selected will

light up and stay lit, and the price will be updated to the new selection.

Insert the coins or tokens requested. The display will show the price or the number of tokens left to start the

selected program.

It is possible to change the selected program and/or extra options while inserting the coins or tokens. The

price of the program adapts according to the new selection and the value of the coins or the number of

tokens introduced will remain in the memory. The newly selected program will be displayed on the LED

relating to the key.

Once all the coins or tokens have been inserted, the selected wash program will start.

4.4.3. Door lock

Door lock. After giving the start order, a 30-second safety time is started during which the drum rotation

and the water inlet operate at short impulses and door remains released. At the end of this time, the locking

mechanism closes and the wash cycle begins.

Throughout the program’s duration, the door remains locked until the LED indicating the end of the program

lights.

Risk of entrapment

To avoid the risk that, while playing, a child gets entrapped inside a washer IT IS CAUTIONED THAT:

After giving the start order, a 30-second safety time is started during which the drum rotation and the

water inlet operate at short impulses and door remains released.

Program execution mode 17

Cod. 598144

Rev. 12/1218

DOOR FITTED WITH SAFETY LOCK

Never attempt to open the door if:

the program has not finished.

the drum has not come to a complete halt.

the bath has not been completely evacuated.

4.5. Program application and contents

In the default configuration, the program content is defined as indicated in the following charts:

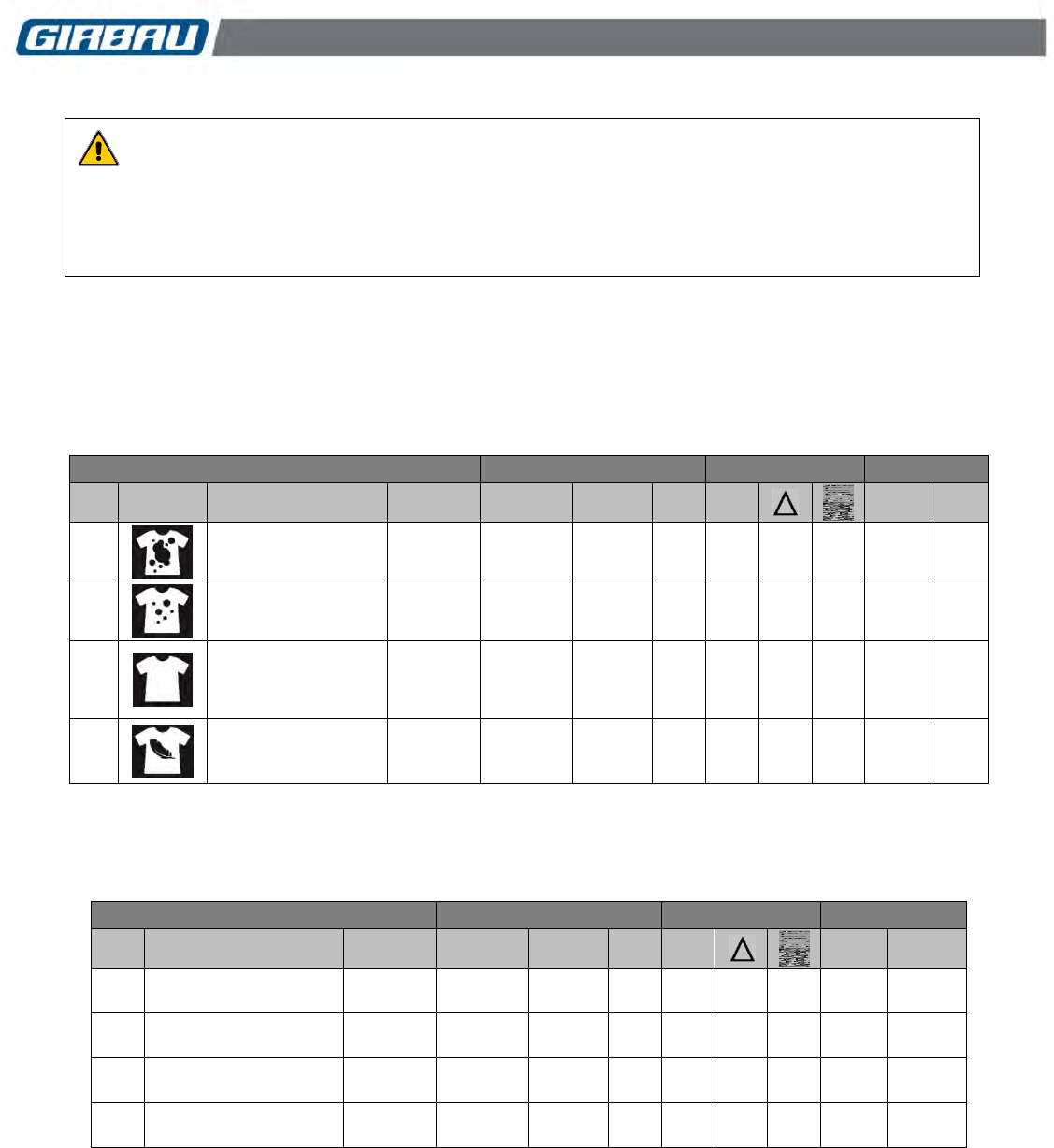

General application programs

HS, RMS and RMG models

PROGRAM

WASH

RINSES

FINAL SPIN

No.

icon

application

estimated

time

rotation

ºC

min

No.

type

min

1

HEAVY SOILED

Cotton. Very dirty

poly-cotton

31 min

heavy

duty

50

10

3

high

6

2

SOILED

Cotton. Poly-cotton.

with normal soiling

31 min

heavy

duty

40

10

3

high

6

3

NORMAL

Poly-cotton.

Synthetics

with normal soiling

29 min

heavy

duty

30

8

3

high

6

4

DELICATE

Wool. Synthetics.

Mixture

26 min

normal

20

10

3

mediu

m

3

USA / CANADA programs

EH, REM and RMG models. SP-0

PROGRAM

WASH

RINSES

FINAL SPIN

No.

application

estimated

time

rotation

ºF / ºC

min

No.

type

min

1

SUPER WASH

Heavy soil

22 min

heavy

duty

90 / 32

7

2

high

6

2

HOT

White

19 min

heavy

duty

90 / 32

4

2

high

6

3

WARM

Color-fast. Perm press

19 min

heavy

duty

82 / 28

4

2

high

6

4

COLD

Colors.Normal

19 min

normal

32 / 00

4

2

high

6

Program execution mode 18

Cod. 598144

Rev. 12/1218

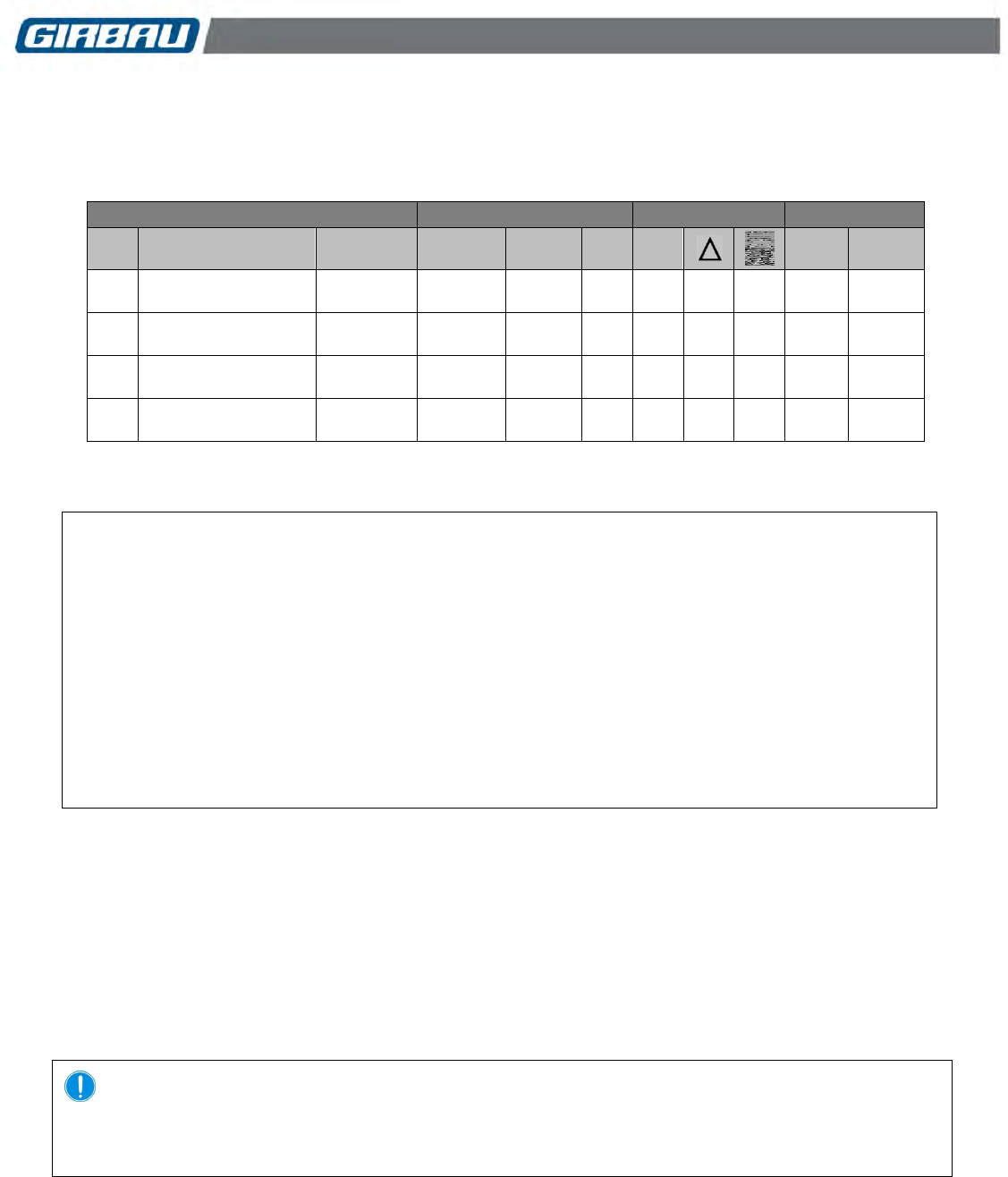

USA / CANADA programs

EH020 and REM025 models. SP-1, SP-2, SP-3

Other EH, REM and RMG models.SP-1

PROGRAM

WASH

RINSES

FINAL SPIN

No.

application

estimated

time

rotation

ºF / ºC

min

No.

type

min

1

SUPER WASH

Heavy soil

26 min

heavy

duty

113 / 45

7

3

high

6

2

HOT

White

23 min

heavy

duty

104 / 40

7

2

high

6

3

WARM

Color-fast. Perm press

23 min

heavy

duty

86 / 30

7

2

high

6

4

COLD

Colors.Normal

21 min

normal

68 / 20

7

2

mediu

m

4

AREA OF USE JPN in CONFIGURATION menu

Program contents

CP option OFF (CP-0) in the MACHINE CONFIGURATION menu.

The content of the four programs is the same as in the Programs for general application configuration -

HS, RMS and RMG models.

CP option ON (CP-I) in the MACHINE CONFIGURATION menu.

The content of the first three programs is the same as in the Programs for general application

configuration - HS, RMS and RMG models.

Program 4 transforms into a program of very short duration (less than 2 minutes), designed for washing

the machine’s drum before loading the clothes for a wash cycle.

The values of the DRUM CLEANING program cannot be modified, except for the bath level, which will

be the level programmed in Phase 6 of this program.

See Sections 6.1 and 6.2 for further information.

4.6. Unbalance control

Before starting the spin, the washing machine’s electronic control checks the correct distribution of the load.

If it detects that the load is not well distributed and that can cause an excessive unbalance during the spin, a new

positioning of the clothes will be carried out.

If there’s still unbalance during the spin of the last phase, the washer can end the washing cycle reducing the

spin speed. If this is the situation, the report End/bAL will be showed alter the delay of the door opening.

Unbalance control with a micro-switch. Activates only in cases of extreme unbalance.

To improve the efficiency of the washer’s spin, it is advisable to:

Load the washer until its nominal value

Load the washer with homogeneous loads

Program execution mode 19

Cod. 598144

Rev. 12/1218

4.7. Stop modes

4.7.1. End of cycle and door opening

The End report will be displayed.

The buzzer and the LED indicating the end of the cycle inform that the program has finished and the door lock is

released.

From this moment on, the door can be opened.

Failure in the realising of the door

At the end of a cycle, if the end of cycle warning LED is not illuminated or a countdown of 120 seconds appears

on the display, push the door firmly using the handle and press any key on the keyboard to start a new attempt at

unlocking the safety lock.

If the problem persists, wait for a minimum of three minutes until the thermal locking device allows the door to

unlock.

4.7.2. Pressing the STOP key

Pressing the interrupts the programme being executed.

The drum stops rotating and the drain valve opens.

At the end of the safety delay, the buzzer informs the user that door lock is unlocked and the display shows

STOP – PUSH – Pr-* (number of program being executed).

From this moment onwards:

One press on the key corresponding to the program currently being executed resumes the cycle.

Opening the door cancels the cycle.

STOP key operating options

A parameter from the CONF menu can be used to select two different options for operating the STOP key.

Selectable options:

Immediate response

Pressing the STOP key immediately stops the program that is running.

Delayed response

To stop the program that is running, hold the key down continuously for at least 3 seconds.

Warnings regarding the HOLD STOP KEY DELAYED RESPONSE

Option available on machines with software Version 31 / 65 and later (see Section 1).

Option unavailable in machines configured for Japan Area of use.

To use this operating option, the corresponding parameter must be enabled in the machine’s

CONFIGURATION menu. This operation must be carried out by the Authorised Technical

Service.

The HOLD STOP KEY DELAYED RESPONSE option can only be activated on machines that

have the message “Push and hold for 3 seconds” inscribed next to the STOP key.

Program execution mode 20

Cod. 598144

Rev. 12/1218

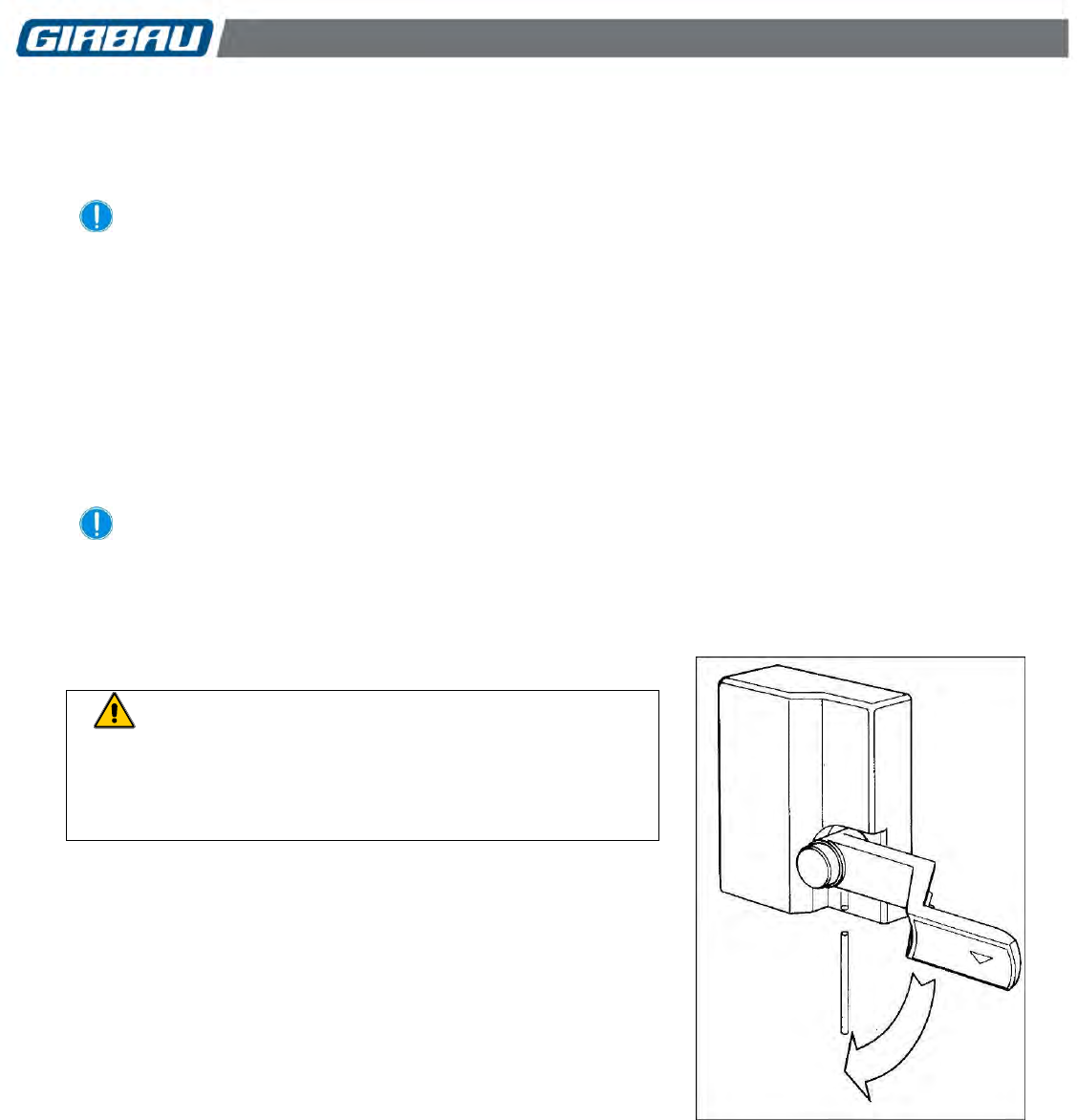

4.7.3. Interruption of the power supply

These stop modes are not recommended, except in an emergency.

They may be caused by turning off the external switch, by activating the laundry’s general emergency stop (see

Installation Manual) or by a fault in the power supply.

In these cases the unlocking of the safety lock may be delayed for up to three minutes.

If the is door closed when the power supply is restored, the machine will interpret that there has been a power

failure and will resume the washing program in progress.

When a washing program is interrupted by electrical power failure or activating the general

Emergency Stop of the installation, the door lock mechanism stops being controlled by the

microprocessor and the opening of the door is thermally delayed.

In these cases the unlocking of the safety lock may be delayed for up to three minutes.

On restoring the power supply, it is normal for the washer to remain inactive for approximately 3 minutes.

On machines with pumped draining or a valve that is normally closed, interruption of the power

supply prevents the bath from being drained.

Advanced use mode 21

Cod. 598144

Rev. 12/1218

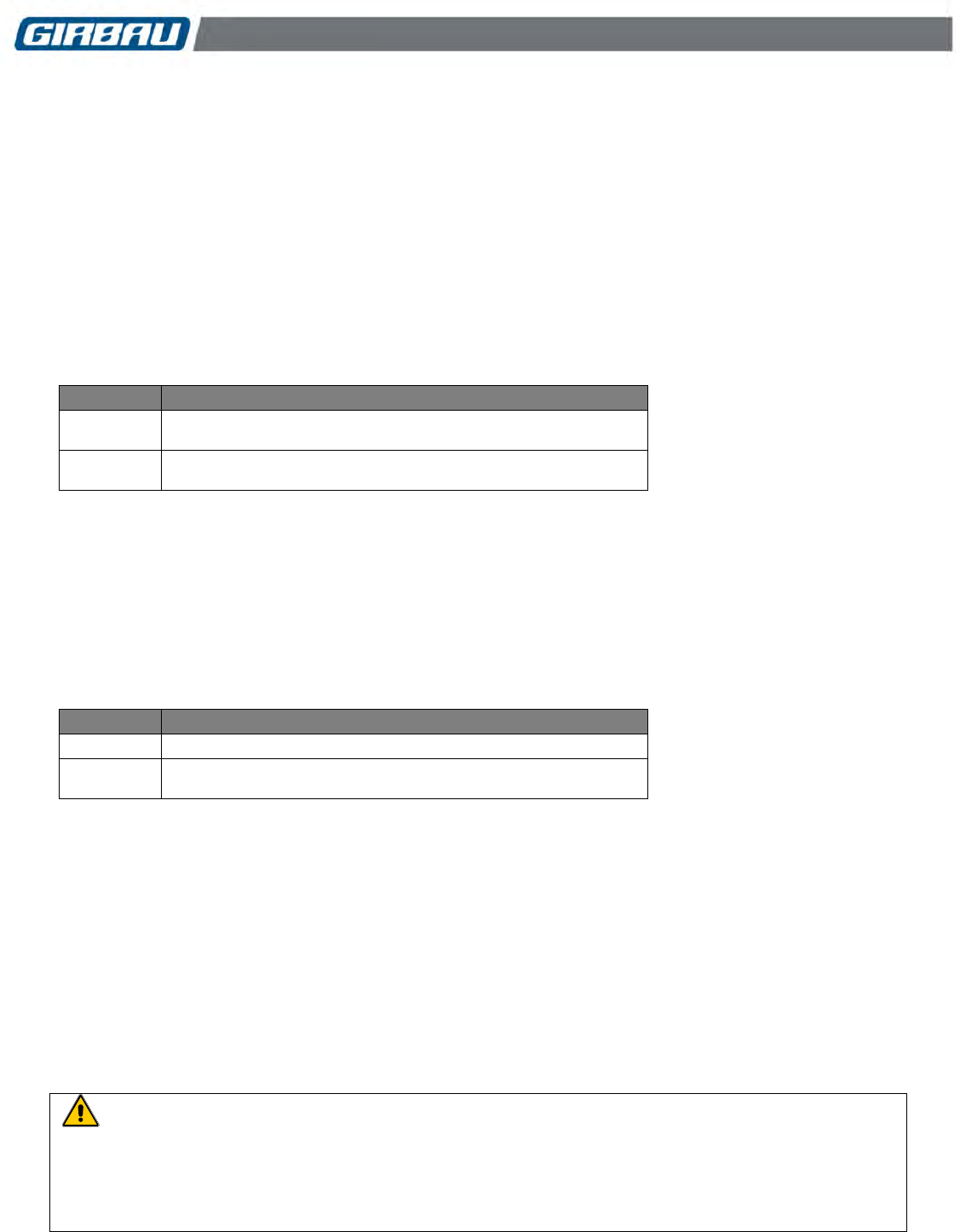

5. ADVANCED USE MODE

The ADVANCED USE MODE offers some menus, which allow the modification of program contents, the price

management of the programs, the modification of operating parameters, etc.

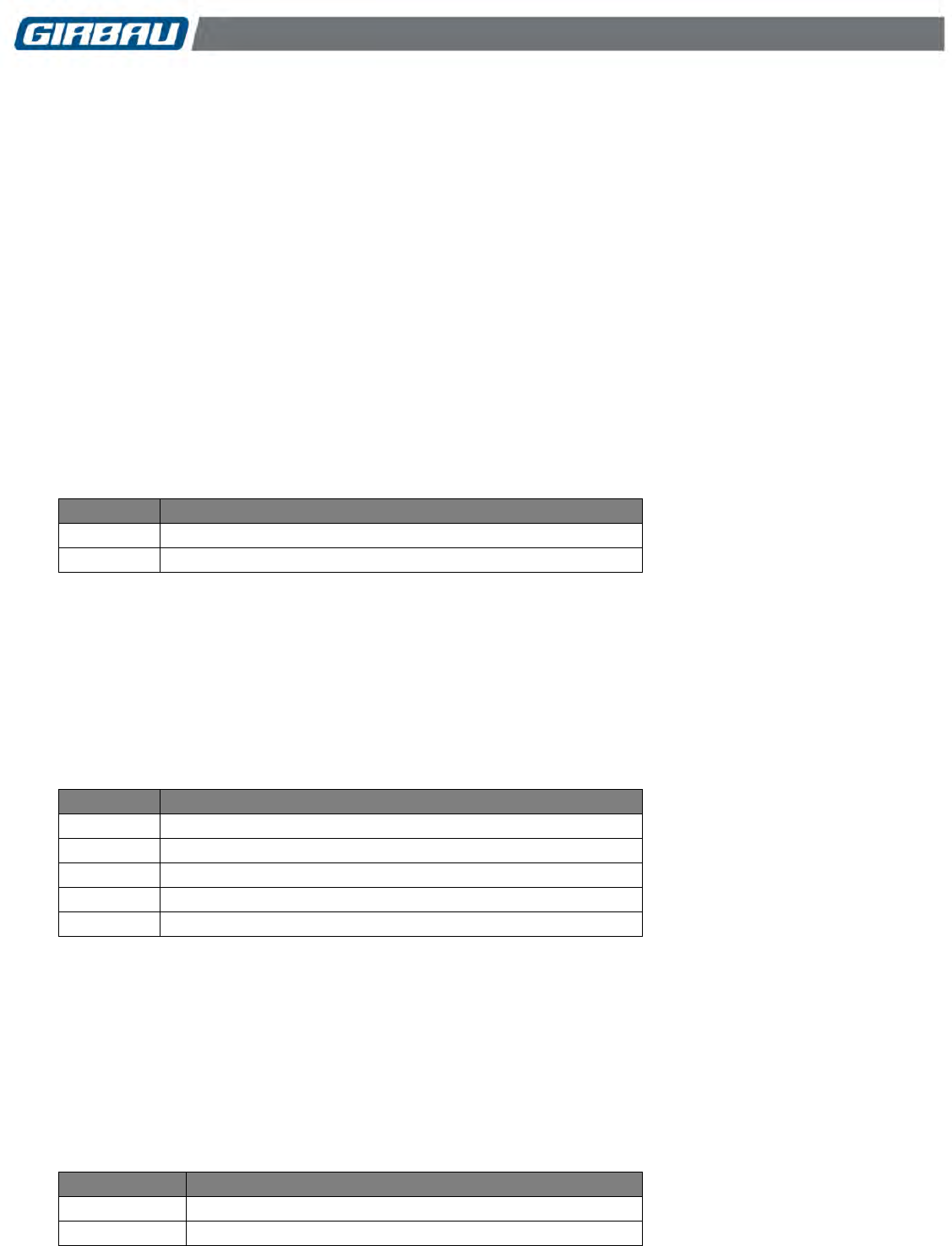

The ADVANCED USE MODE is made up of the menus defined in the following chart.

MENU

PURPOSE

CHAPTER /SECT.

Pro

Modification of the program contents

6

dEmo

Operation mode with program accelerator

7

InFO

Information menu

8

Mod

Modification of operation parameters

9

NCod

Modifying of the access code

10

CASH

Programming and/or modifying each program price

11.1; 11.2.3

Hour

Adjustment of the system time

11.2.1

CALE

Prices allocation according to hour band

11.2.2

EoPt

Options menu

12

5.1. Access to the ADVANCED USE MODE

Connect the washer and open the door. The display will show door.

Press and hold down key 1 until the Cod report appears on the display.

Enter the access code into the menus by pressing the sequence of eight keys of the code without interruption.

In basic configuration (when the machine is delivered) the access code to ADVANCED MODE is: 12341234.

If the sequence entered is correct, the display will show Pro, corresponding to the first menu ADVANCED

MODE.

Keys 2 and 4 allow the selection of the precedent table menus. The menu selected is shown on the display

following its keyword. To enter in it, press key 1 when displaying it.

If wished to skip the ADVANCED MODE, press and machine will return to program execution mode.

6. MODIFICATION OF THE PROGRAM CONTENTS. Menu Pro

In its original configuration, the washing machine has four wash programs with content adapted to a wide range

of usage. However, the content of each program can be modified to be adapted to the specific needs of different

situations.

The modifications are always made from a MASTER PROGRAM that includes the possible programmable

parameters and the maximum and minimum values of certain options.

The master program is composed of six phases. At the start of each phase, a parameter of the value Ph-Y / Ph-

N (executable phase YES / executable phase NO) will allow the user to determine whether the accessed phase

should either be executed or omitted.

Once the phase is defined as to be executed, proceed to the display and modification (if desired) of the

parameters or values of the phase.

STOP

Modification of the program contents 22

Cod. 598144

Rev. 12/1218

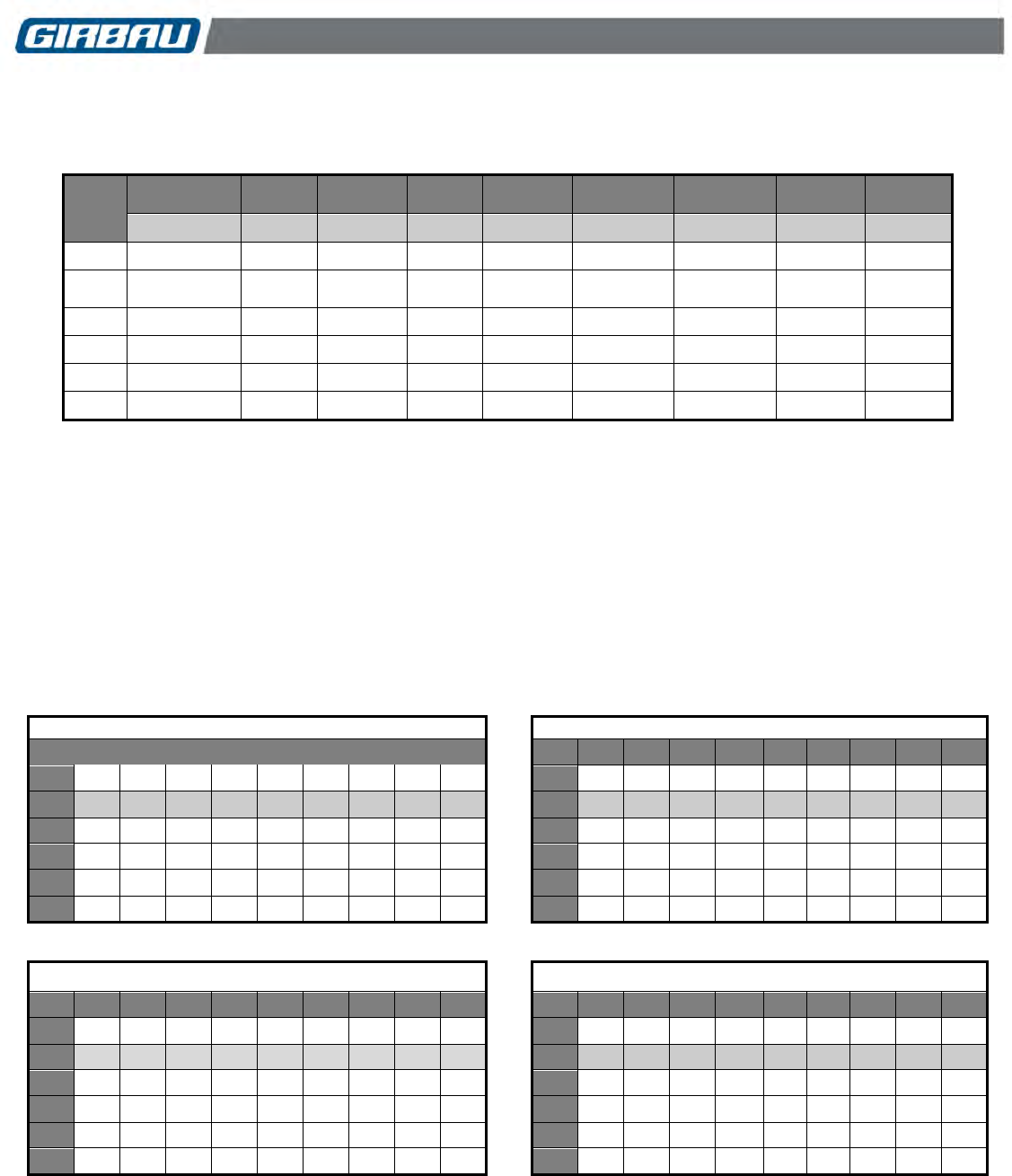

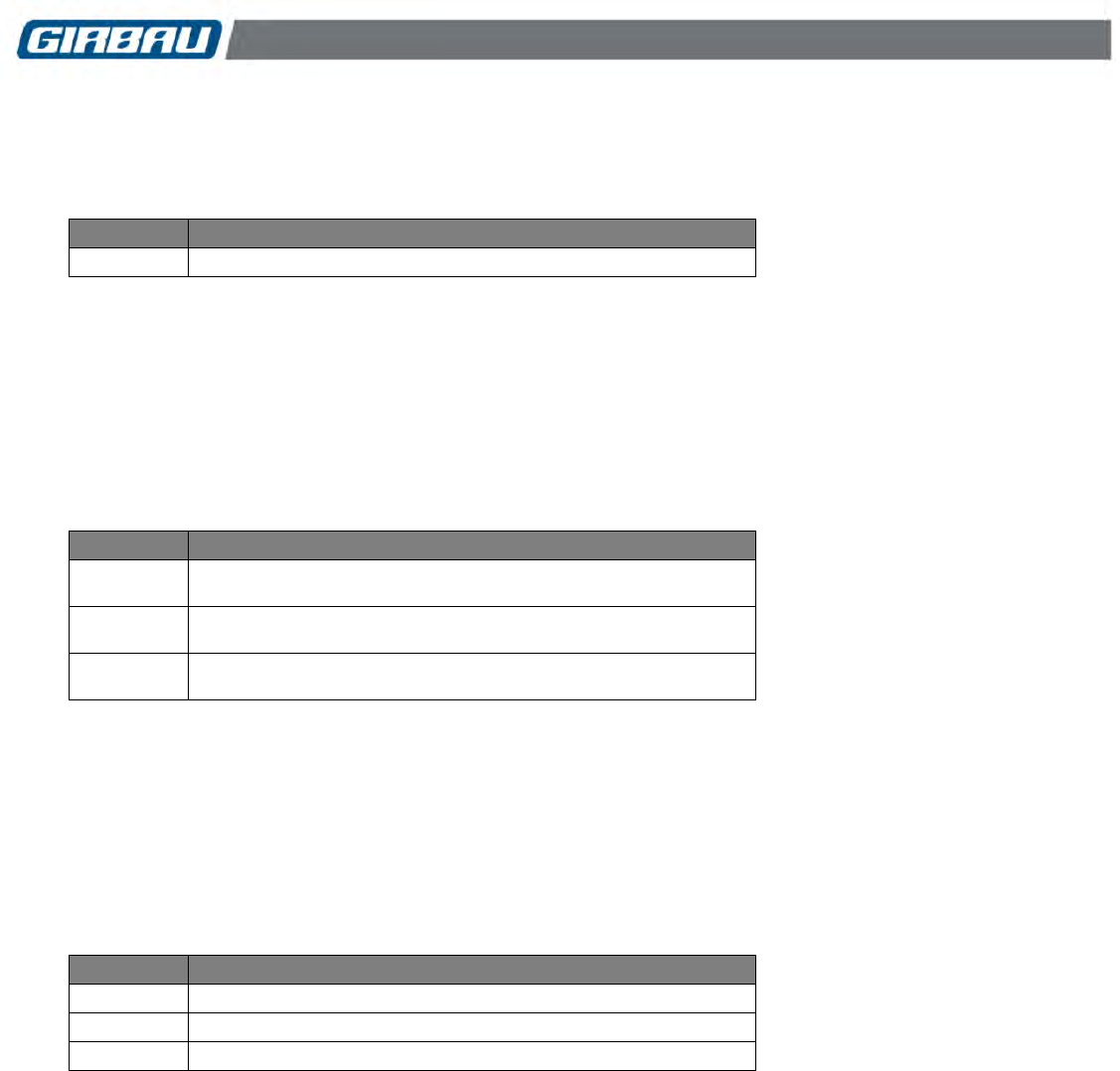

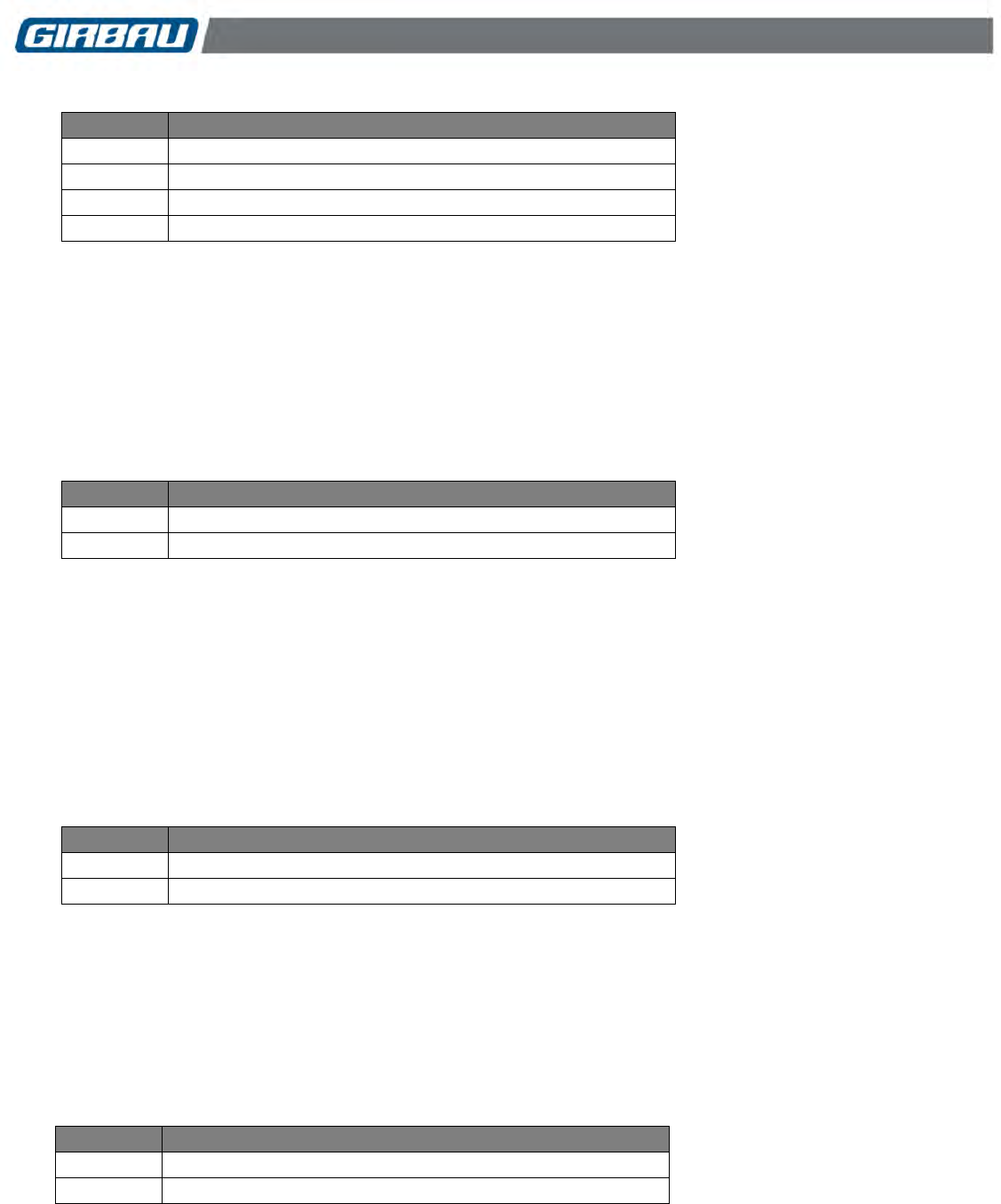

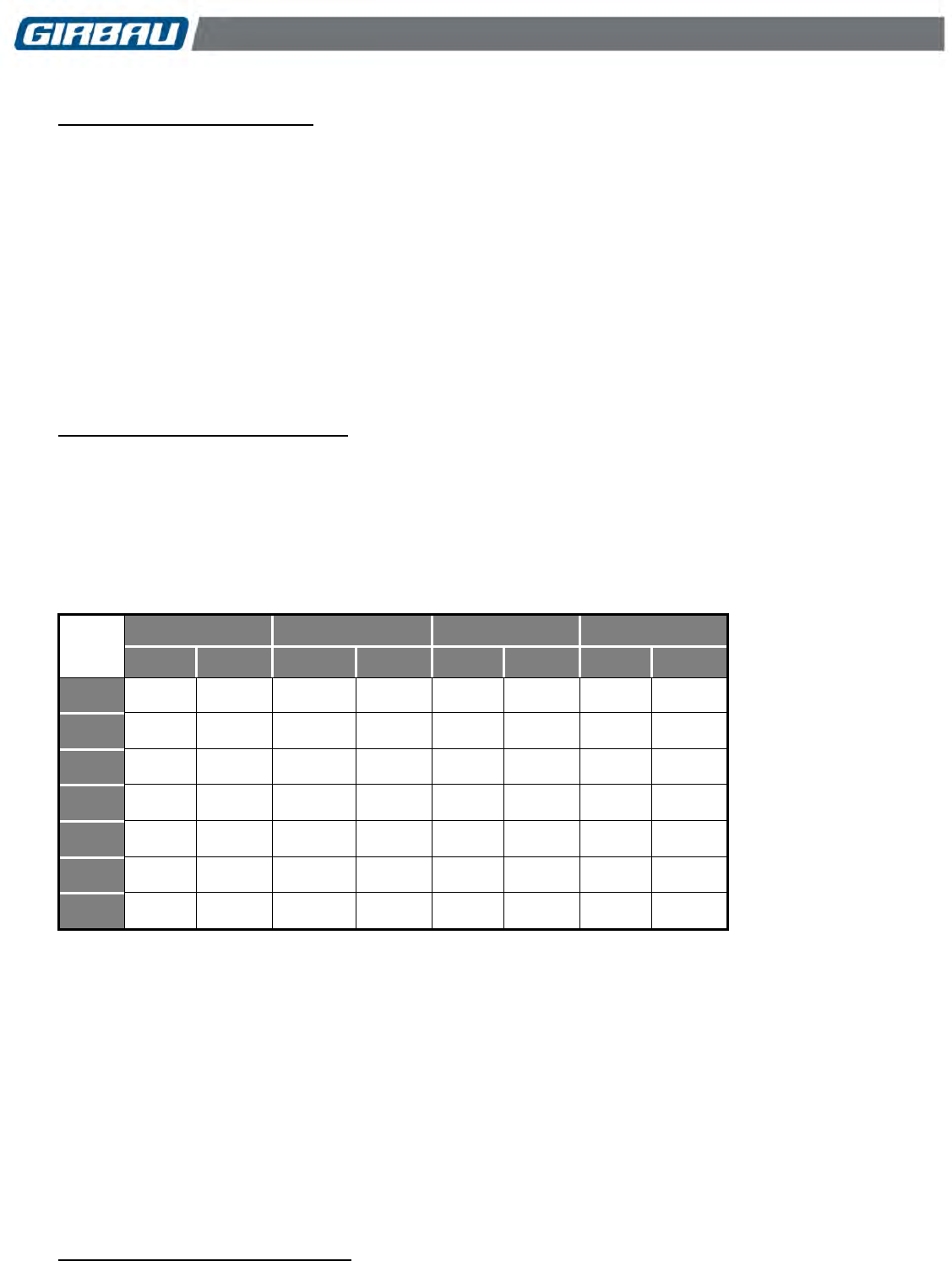

6.1. Master program

PHASE

EXECUTION

LEVEL

TEMP.

DISP.

TIME DISP.

ROTATION

ROTATION

TIME

EXTRACT

EXTRACT

TIME

Ph

L

C / F

d

t

r

rt

E

Et

1

Y / N

0…4

n.p.

0…3.4

1…99

1...3

0...6

0...3

n.p. 2...3

2

Y / N

0…4

0 ... 80

32 ... 176

0…3.4

1…99

1...3

0...20

0…2

n.p. 2

3

Y / N

0…4

n.p.

0…3.4

1…99

1...3

0...6

0…3

n.p. 2...3

4

Y / N

0…4

n.p.

0…3.4

1…99

1...3

0...6

0…3

n.p. 2...3

5

Y / N

0…4

n.p.

0…3.4

1…99

1...3

0...6

0 , 1

n.p.

6

Y

1…4

n.p.

0…3.4

1…99

1...3

1...6

1...6

n.p. 2...7

See Sections 6.2, 6.3 and 6.4 for the definition of the phases, functions and values programmable in each

phase.

See the warnings on machines configured for Area of use - JPN in Section 4.5

6.2. Original content of the programs

6.2.1. Program contents

All models

Pr - 1. HEAVY SOILED 31 min

Pr - 2. SOILED 31 min

Ph

Ph

L

C

d

t

r

rt

E

Et

Ph

Ph

L

C

d

t

r

rt

E

Et

1

N

2

- - -

1

30

1

3

1

1

1

N

2

- - -

1

30

1

3

1

1

2

Y

1

50

2

30

1

10

1

1

2

Y

1

40

2

30

1

10

1

1

3

Y

2

- - -

3

30

1

3

1

1

3

Y

2

- - -

3

30

1

3

1

1

4

Y

3

- - -

- - -

- - -

1

2

2

2

4

Y

3

- - -

- - -

- - -

1

2

2

2

5

N

3

- - -

- - -

- - -

1

2

1

1

5

N

3

- - -

- - -

- - -

1

2

1

1

6

Y

2

- - -

4

30

1

2

6

6

6

Y

2

- - -

4

30

1

2

6

6

Pr - 3. NORMAL 29 min

Pr - 4. DELICATE 26 min

Ph

Ph

L

C

d

t

r

rt

E

Et

Ph

Ph

L

C

d

t

r

rt

E

Et

1

N

2

- - -

1

30

1

3

1

1

1

N

2

- - -

1

30

2

3

1

1

2

Y

1

30

2

30

1

8

1

1

2

Y

1

20

2

30

2

10

1

1

3

Y

2

- - -

3

30

1

3

1

1

3

Y

2

- - -

3

30

2

2

1

1

4

Y

3

- - -

- - -

- - -

1

2

2

2

4

Y

3

- - -

- - -

- - -

2

2

1

1

5

N

3

- - -

- - -

- - -

1

2

1

1

5

N

3

- - -

- - -

- - -

2

2

1

1

6

Y

2

- - -

4

30

1

2

6

6

6

Y

2

- - -

4

30

2

2

4

3

Modification of the program contents 23

Cod. 598144

Rev. 12/1218

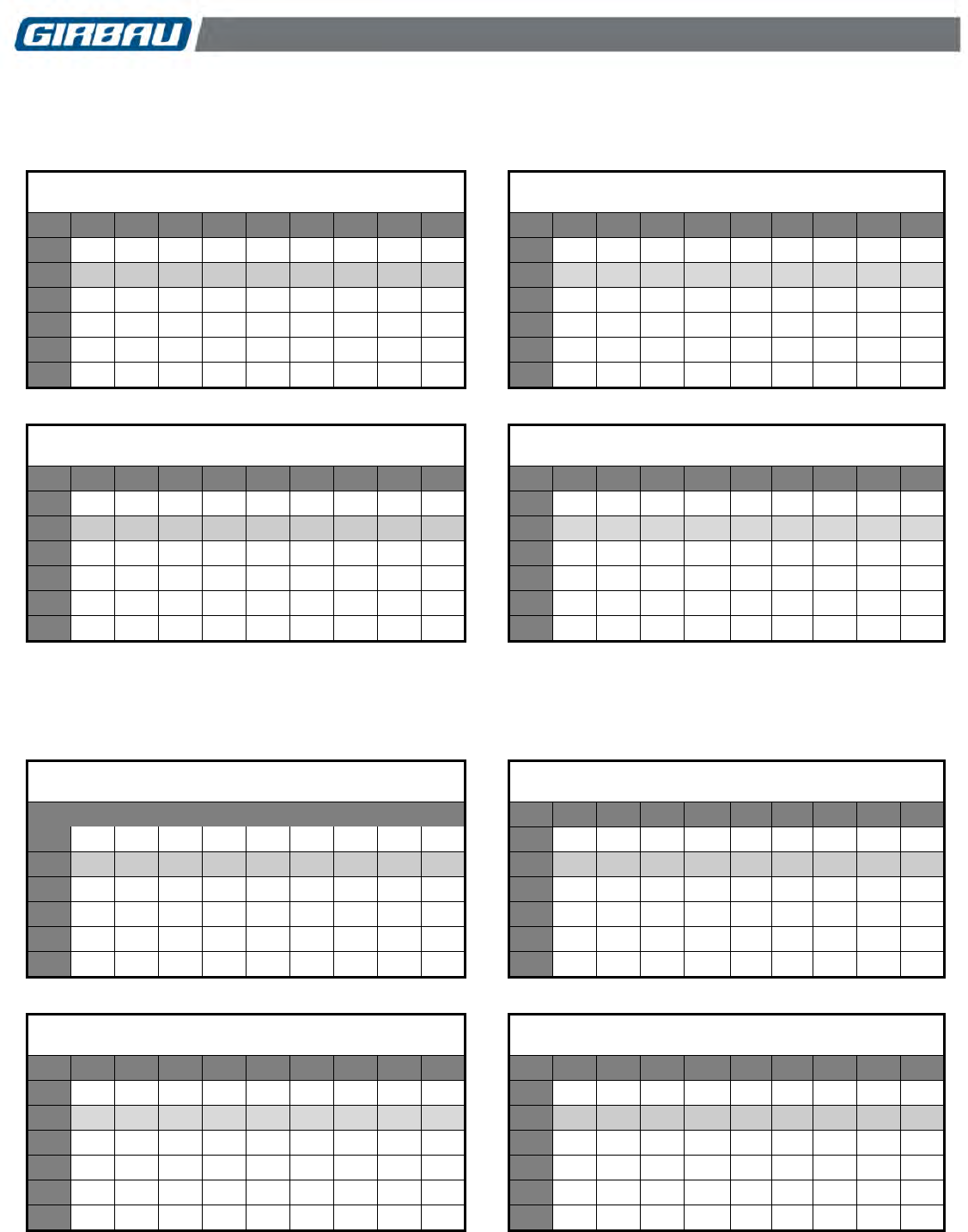

6.2.2. Program contents. USA configuration

All models. SP-0

PR - 1. SUPER WASH 22 min

HEAVY SOIL

PR - 2. HOT 19 min

WHITE

Ph

Ph

L

F

d

t

r

rt

E

Et

Ph

Ph

L

F

d

t

r

rt

E

Et

1

N

2

- - -

1

30

1

4

2

2

1

N

2

- - -

1

30

1

3

2

2

2

Y

1

90

2

30

1

7

1

1

2

Y

1

90

2

30

1

4

1

1

3

Y

1

- - -

3

30

1

2

1

1

3

Y

2

- - -

3

30

1

2

1

1

4

N

2

- - -

- - -

- - -

1

1

1

1

4

N

2

- - -

- - -

- - -

1

1

1

1

5

N

2

- - -

- - -

- - -

1

1

1

1

5

N

2

- - -

- - -

- - -

1

1

1

1

6

Y

2

- - -

4

30

1

2

6

(*)

6

6

Y

2

- - -

4

30

1

2

6

(*)

6

PR - 3. WARM 19 min

COLOR-FAST. PERM PRESS

PR - 4. COLD 19 min

COLORS. NORMAL

Ph

Ph

L

F

d

t

r

rt

E

Et

Ph

Ph

L

F

d

t

r

rt

E

Et

1

N

2

- - -

1

30

1

3

2

2

1

N

2

- - -

1

30

1

3

2

2

2

Y

1

82

2

30

1

4

1

1

2

Y

1

32

2

30

1

4

1

1

3

Y

2

- - -

3

30

1

2

1

1

3

Y

2

- - -

3

30

1

2

1

1

4

N

2

- - -

- - -

- - -

1

1

1

1

4

N

2

- - -

- - -

- - -

1

1

1

1

5

N

2

- - -

- - -

- - -

1

1

1

1

5

N

2

- - -

- - -

- - -

1

1

1

1

6

Y

2

- - -

4

30

1

2

6

(*)

6

6

Y

2

- - -

4

30

1

2

6

(*)

6

EH020 and REM025 models. SP-1, SP-2, SP-3

Other EH, REM and RMG models. SP-1

PR - 1. SUPER WASH 26 min

HEAVY SOIL

PR - 2. HOT 23 min

WHITE

Ph

Ph

L

F

d

t

r

rt

E

Et

Ph

Ph

L

F

d

t

r

rt

E

Et

1

N

2

- - -

1

30

1

2

2

2

1

N

2

- - -

1

30

1

2

2

2

2

Y

2

113

2

30

1

7

1

1

2

Y

2

104

2

30

1

7

1

1

3

Y

2

- - -

3

30

1

2

3

2

3

Y

2

- - -

3

30

1

2

3

2

4

Y

2

- - -

- - -

- - -

1

1

1

1

4

N

2

- - -

- - -

- - -

1

1

1

1

5

N

3

- - -

- - -

- - -

1

1

1

1

5

N

2

- - -

- - -

- - -

1

1

1

1

6

Y

2

- - -

4

30

1

2

6

(*)

6

6

Y

2

- - -

4

30

1

2

6

(*)

6

PR - 3. WARM 23 min

COLOR-FAST. PERM PRESS

PR - 4. COLD 21 min

COLORS. NORMAL

Ph

Ph

L

F

d

t

r

rt

E

Et

Ph

Ph

L

F

d

t

r

rt

E

Et

1

N

2

- - -

1

30

1

2

2

2

1

N

2

- - -

1

30

1

2

2

2

2

Y

2

86

2

30

1

7

1

1

2

Y

2

68

2

30

1

7

1

1

3

Y

2

- - -

3

30

1

2

3

2

3

Y

2

- - -

3

30

1

2

3

2

4

N

2

- - -

- - -

- - -

1

1

1

1

4

N

2

- - -

- - -

- - -

1

1

1

1

5

N

2

- - -

- - -

- - -

1

1

1

1

5

N

2

- - -

- - -

- - -

1

1

1

1

6

Y

2

- - -

4

30

1

2

6

(*)

6

6

Y

2

- - -

4

30

1

2

6

(*)

4

(*) In Models RMG033/40/55/70 the default spin value is 5.

Modification of the program contents 24

Cod. 598144

Rev. 12/1218

6.3. Definition of phases

PHASE

S

DEFINITION

1

2

3

4

5

6

Pre-wash. Optional execution phase.

Wash. Obligatory execution phase. The mixing of hot and cold water and/or water

heating is permitted.

First Rinse. Obligatory execution phase.

Second rinse. Optional execution phase.

Third rinse. Optional execution phase.

Fourth rinse. Obligatory execution phase.

6.4. Definition of programmable functions and values for each phase

FUNCTION

CONCEPT

OPTIONS

Ph

Phase execution

Ph-Y

Phase can be executed

Ph-N

Phase cannot be executed

L

Bath level

L-0

Phase without water inlet

L-1

Low level

L-2

Medium level

L-3

High level

L-4

Extra high level

C / F

Wash phase

temperature

0 / 80

Programmable range in degrees Celsius

32 / 176

Programmable range in degrees Fahrenheit

n.p.

Temperature cannot be programmed in the phase

d

Dosings

d-0

Phase without dosing

d-1

Dosing of powdered detergent

d-2

Dosing of powdered detergent

d-3

Dosing of liquid dosing

d-4

Dosing of liquid dosing

t

Dosing time

1 … 99

Programmable time in seconds

r

Rotation type

r-1

Heavy duty rotation: 25 sec. ON - 5 sec. OFF

r-2

Normal rotation: 15 sec. ON - 15 sec. OFF

r-3

Light rotation: 5 sec. ON - 25 sec. OFF

rt

Rotation time

(in minutes)

0

Phase without rotation

1...6

Programmable range in the pre-wash phase

1...20

Programmable range in the wash phase

1...6

Programmable range in the rinse phase

E

Bath drain

0

Phase without draining

1

Drain + wash speed

2

Drain + positioning speed

3

Drain + low spin speed

4

Drain + medium spin speed

5

Drain + medium/high spin speed

6

Drain + high spin speed

Et

Spin time

n.p.

Time not programmable

2...3

Programmable range in intermediate spins

2...7

Programmable range in E-4 - E-6 spins

For further information on the programmable functions, see section below.

Modification of the program contents 25

Cod. 598144

Rev. 12/1218

6.5. Modifying a program

Access the ADVANCED MODE (Section 5.1). The display shows Pro.

Press key 1 to access the PROGRAMMING menu.

The display shows Pr-1. Program 1 is ready for modification. The 2 / 4 keys allow the selection of another

menu. Press key 1 to access the modification of the displayed program.

The display shows Pr-1. Phase 1 is ready for modification. The 2 / 4 keys allow the selection of another phase.

Press key 1 to start the modification to the values of the selected phase.

When the number of the phase is displayed (at the start of phase), the STOP key is used to finalise the program

modification.

Once a program modification has been finalised, the display will show the Pr-* (modified program). Pressing the

STOP key once allows the user to access the higher level of the menu. Pressing twice consecutively allows the

user to exit the ADVANCED USE MODE.

Activation of the phase

Allows the user to program the execution of the selected phase.

Once the desired phase to be modified has been selected, press the 1 key. The display shows Ph-*.

OPTIONS

MEANING

Ph-Y

The phase to be executed is available

Ph-N

The phase to be executed is unavailable

Phases 2, 3 and 6 are phases of obligatory execution.

The 2 / 4 keys allow the modification of the option displayed.

The 1 key validates the selection on the display and allows the user to access the following programmable

function.

Bath level

Bath level allows the selection of the bath level inside the washer.

OPTIONS

MEANING

L-0

Phase without water inlet. Programmable only in phase 1.

L-1

Low level

L-2

Medium level

L-3

High level

L-4

Extra high level

For safety reasons, options L-3 and L-4 are not programmable in machines with a pump drain or a valve closed

without current.

The 2 / 4 keys allow the modification of the option displayed.

The 1 key validates the selection on the display and allows the user to access the following programmable

function.

Temperature of the washing phase

Allows modifying the water temperature in the washing phase. In other phases, it is not possible to program the

water temperature.

OPTIONS

MEANING

C-0 ... C-80

Programmable range in degrees Celsius

F 32 ... F 176

Programmable range in degrees Fahrenheit

The 2 / 4 keys allow the modification of the option displayed.

The 1 key validates the selection on the display and allows the user to access the following programmable

function.

Modification of the program contents 26

Cod. 598144

Rev. 12/1218

Dosings

This allows the user to activate or deactivate the dosing signals that appear in the master table.

If product dosing occurs via the machine’s dispenser, the dosing options are as follows (see dispenser

distribution in Section 4.3).

OPTIONS

MEANING

d- 0

Without dosing

d- 1

Powdered detergent. Normally used in the pre-wash phase

d- 2

Powdered detergent. Normally used in the wash phase

d- 3

Liquid product. Normally used for bleaching (chloride, bleach, etc.)

d- 4

Liquid product. Normally used as a softener/neutraliser

n.p.

Dosing cannot be programmed in the phase

Other possible programming options:

OPTIONS

MEANING

d-12

Simultaneous activation of dosings 1 and 2.

d-13

Simultaneous activation of dosings 1 and 3.

d-14

Simultaneous activation of dosings 1 and 4.

d-23

Simultaneous activation of dosings 2 and 3.

d-24

Simultaneous activation of dosings 2 and 4.

d-34

Simultaneous activation of dosings 3 and 4.

The 2 key allows the user to modify the option displayed.

The 1 key validates the selection on the display and allows the user to access the following programmable

function.

Phase 1 peculiarity

Application designed for machines connected to an external dosing control unit and using this unit’s

own dosing programs.

Phase 1 allows the value 0 to be programmed in the level, rotation time and bath draining functions, using the

dosing and dosing time signals to inform the central dosing unit of the program selected in the washer. After

receiving this information, the central dosing unit will execute the appropriate product dosings for the program

selected in the washer.

Examples of first phase programming used as information to the central dosing unit

Example 1

d

t

information

1

30

Dosing in accordance with Program 1

2

30

Dosing in accordance with Program 2

3

30

Dosing in accordance with Program 3

4

30

Dosing in accordance with Program 4

Example 2

d

t

information

1

2

Dosing in accordance with Program 1

1

4

Dosing in accordance with Program 2

1

6

Dosing in accordance with Program 3

1

8

Dosing in accordance with Program 4

CAUTION!

When dosing signals d3 and d4 are used to inform the central dosing unit, it is advisable to activate the dC

(dispenser cleaning) option in order to remove traces of water from the dispenser. (See Mod menu, Chapter

9)

Modification of the program contents 27

Cod. 598144

Rev. 12/1218

Dosing time

Duration of the dosing or dosings programmed in the phase. Value in seconds.

This only appears only if the dosing value has been programmed in the phase.

OPTIONS

MEANING

1 ... 99

Programmable values

The 2 / 4 keys allow the modification of the option displayed.

The 1 key validates the selection on the display and allows the user to access the following programmable

function.

Rotation

The mechanical action of the washing machine on the linen is different depending on the rotation selected.

Time ON: drum rotating

Time OFF: drum stopped

OPTIONS

MEANING

r-1

Heavy duty rotation

ON: 25 sec. - OFF: 5 sec.

r-2

Normal rotation

ON: 15 sec. - OFF: 15 sec.

r-3

Light rotation

ON: 5 sec. - OFF: 25 sec.

The 2 key allows the user to modify the option displayed.

The 1 key validates the selection on the display and allows the user to access the following programmable

function.

Rotation time

Rotation time programmed in the phase. Time in minutes.

This time is started once the programmed level is reached.

OPTIONS

MEANING

0

Phase without rotation. Programmable only in phase 1.

1 ... 6

Programmable range in the pre-wash and rinse phases

1 ... 20

Programmable range in the wash phase

The 2 / 4 keys allow the modification of the option displayed.

The 1 key validates the selection on the display and allows the user to access the following programmable

function.

Modification of the program contents 28

Cod. 598144

Rev. 12/1218

Bath drain

The draining of the water from the washing machine is achieved by activating of the drain system and a drum

rotation speed.

Options E-1 and E-2 imply a default time value.

The duration of options E-3 – E-6 is programmable within a determined range.

OPTIONS

MEANING

0

Phase without draining. Programmable only in phase 1.

E-1

Drain + wash speed

E-2

Drain + positioning speed

E-3

Drain + low spin speed

E-4

Drain + medium spin speed

E-5

Drain + medium/high spin speed

E-6

Drain + high spin speed

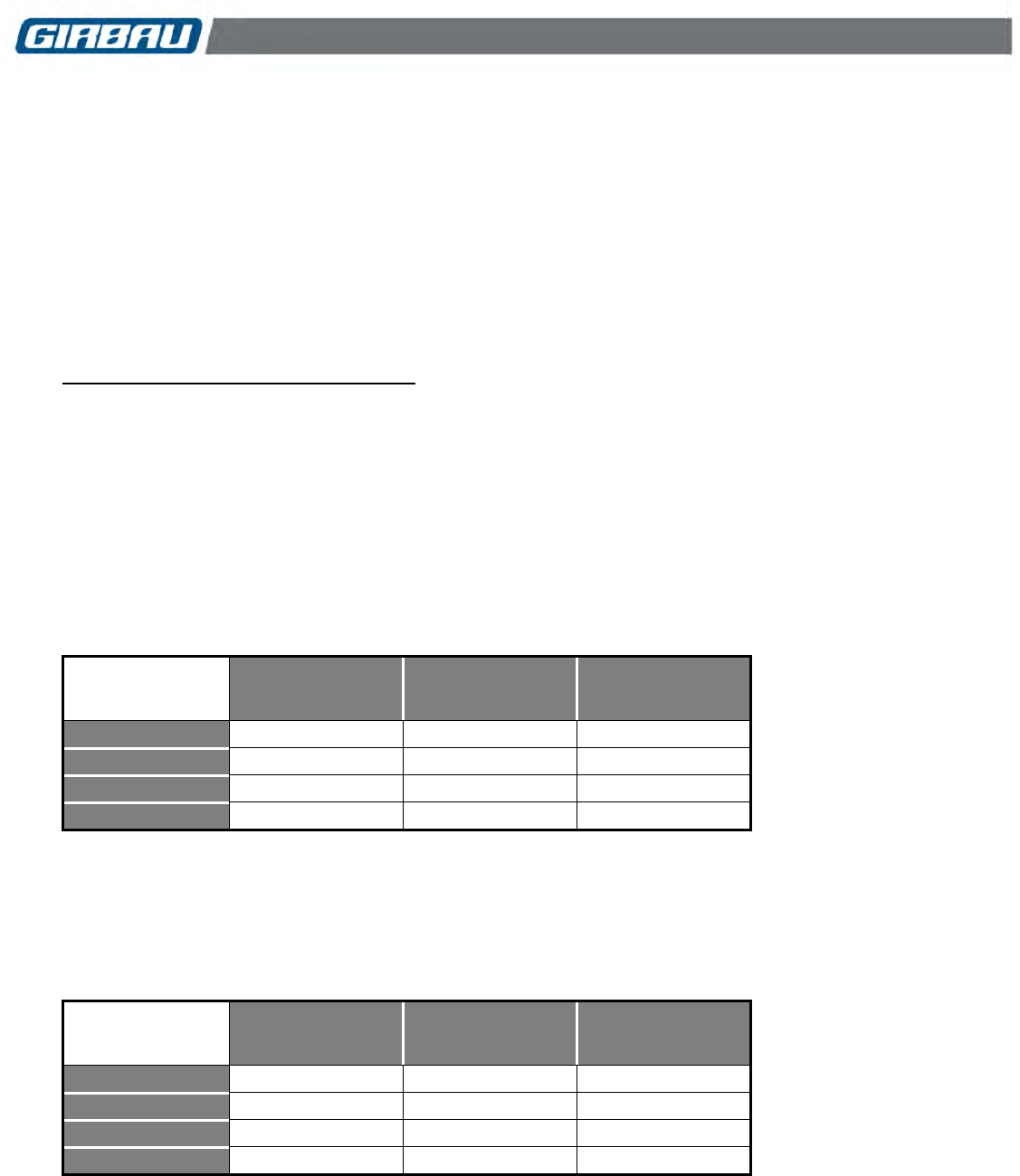

RPM (G FORCE) FOLLOWING MACHINE MODEL

OPTIONS

RMS610

REM025

RMS613

REM033

RMS617

REM040

RMS623

REM055

RMS628

REM070

RMG613

RMG033

RMG617

RMG040

RMG623

RMG055

RMG628

RMG070

E-1

54

47

47

44

40

47

47

45

40

E-2

100

100

100

100

86

100

100

100

86

E-3

410(48)

300(31)

300(31)

300(35)

342(50)

380(50)

380(50)

360(50)

342(50)

E-4

500(75)

400(56)

400(56)

400(63)

433(80)

574(115)

574(115)

505(100)

485(100)

E-5

580(100)

500(87)

500(87)

500(98)

530(120)

635(140)

635(140)

600(140)

570(140)

E-6

600(108)

600(125)

600(125)

600(140)

592(150)

760(200)

760(200)

715(200)

685(200)

RPM (G FORCE) FOLLOWING MACHINE MODEL

OPTIONS

HS-6008

EH020

HS-6013

EH030

HS-6017

EH040

HS-6023

EH055

HS-6024

EH060

HS-6032

EH080

EH090

E-1

50

48

45

43

38

42

40

E-2

100

100

100

87

86

83

79

E-3

400

400

375

330

350

335

325

E-4

600

600

570

525

550

528

490

E-5

800

800

750

725

725

698

675

E-6

970(283)

1000(351)

950(354)

920(350)

966(400)

932(400)

870(381)

The 2 / 4 keys allow the modification of the option displayed.

The 1 key validates the selection on the display and allows the user to access the following programmable

function.

Spin time

Spin time programmed in the phase. Time in minutes.

OPTIONS

MEANING

n.p.

Draining time E-1 and E2

2 ... 3

Programmable range not in final phase of the program

2 ... 7

Programmable range in final phase of the program

The 2 / 4 keys allow the modification of the option displayed.

The 1 key validates the displayed selection and ends the phase programming.

The display will show the following phase.

When finalising the programming of the last phase of the program, display shows Pr-* (modified program).

Demo and Info menu 29

Cod. 598144

Rev. 12/1218

7. OPERATION MODE WITH PROGRAM ACCELERATOR. dEmo Menu

It allows executing one of the four COIN programs with the possibility of reducing the program time.

Program to facilitate maintenance interventions and preparation of programs.

Execution of a program in dEmo mode

Access to the ADVANCED MODE. Section 5.1. The display shows Pro.

Press the 2 key twice. The displays shows CASH and dEmo successively. (In machines with extra options,

press Key 2 three times. The displays shows CASH, EoPt, dEmo successively.

Press the 1 key to access the dEmo menu. The display shows door.

Close the door. The display shows Pr-1.

Ready to execute program 1. Keys 2 and 4 allow the selection of another menu.

Press STOP key to start the program on the display.

The program will be executed following the present contents of it.

During the execution of the program, it is possible to modify it:

Press the 3 key. The information on the display starts flashing.

Press 4 to advance to the following function or to reduce the rotation and spin times.

Key 2 allows increasing the rotation times.

Once the program is finished, open the door.

The washer can be normally used.

8. INFORMATION MENU. InFO menu

Information menu of different parameters.

PARAMETERS

MEANING

COIN

Coin-op washers control

EP**

Program version

Pr-

Total number of cycles run

Pr-1

Number of cycles executed with program 1

Pr-2

Number of cycles executed with program 2

Pr-3

Number of cycles executed with program 3

Pr-4

Number of cycles executed with program 4

EUA

Number of cycles run with extra washing option

Eri

Number of cycles run with extra rinsing option

EdS

Number of cycles run with extra spinning option

SUD

Number of times the anti-suds function has been activated

Access to the ADVANCED MODE. Section 5.1. The display shows Pro.

Press key 2 three times. In the display reports CASH, dEmo, InFO are showed successively. (In machines with

extra options, press Key 2 four times. The displays shows CASH, EoPt, dEmo and InFO successively.)

Press the 1 key to sequentially access the listing of the different parameters and the values of the

corresponding counters.

Once the last option is listed, press the 1 key. The display shows InFO.

The keys 2 and 4 allow the access to other menus.

To exit the ADVANCED MODE press the STOP key.

Modification of operation parameters 30

Cod. 598144

Rev. 12/1218

9. MODIFICATION OF OPERATING PARAMETERS. Mod menu

The Mod menu allows the user to modify the operation parameters of all the programs.

The modifications carried out from Mod menu affect the four programs.

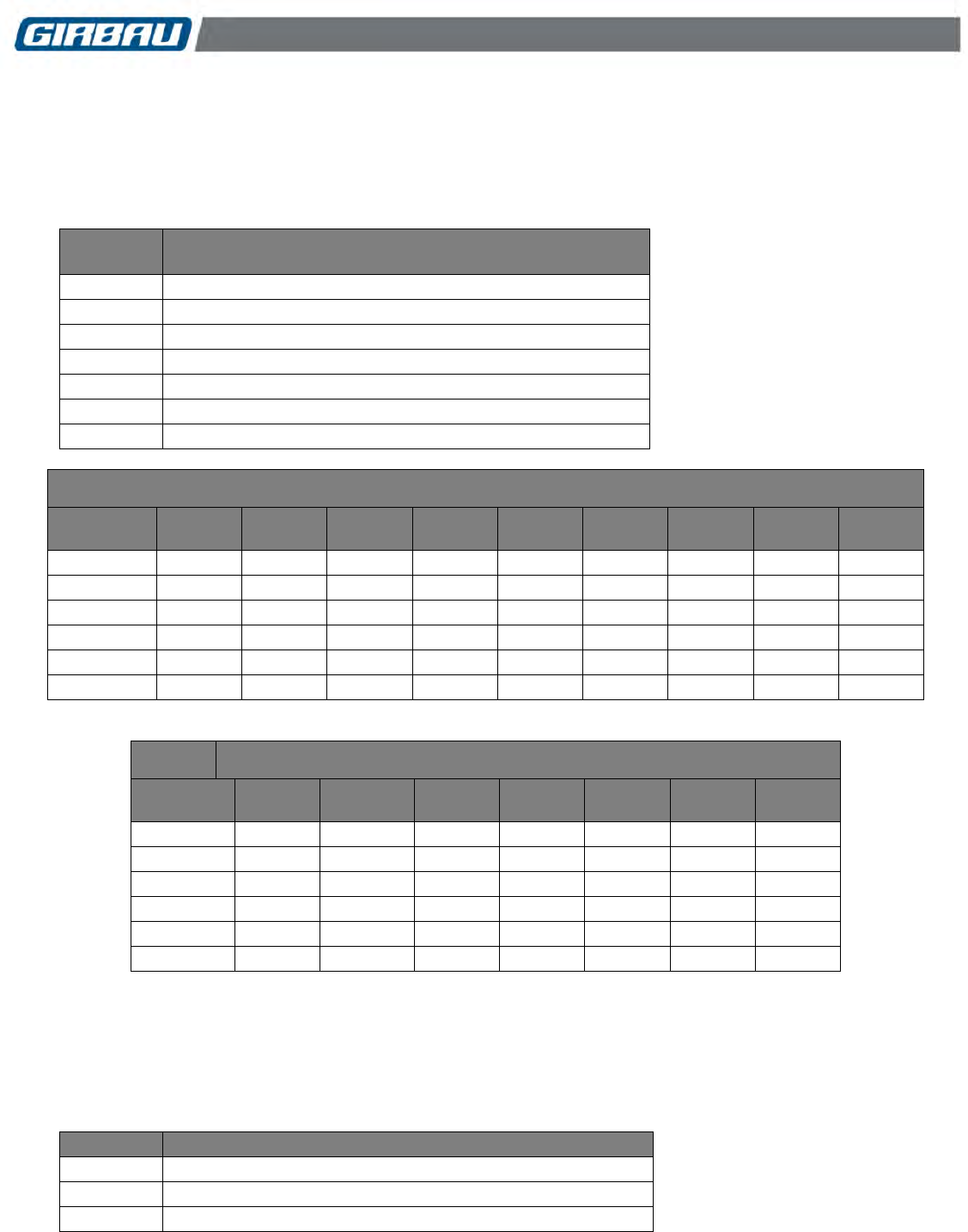

Summary table of the changeable parameters:

PARAMETER

MODIFICATION OF

OPTIONS

CE

USA

C / F

Temperature unit

C

Temperature displayed in degrees Celsius

F

Temperature displayed in degrees Fahrenheit

dc

Cleaning the dispenser

dc-0

Dispenser cleaning NO activated

dc-1

Dispenser cleaning YES activated

Ed

External dosing

Ed-0

Units without external dosing

Ed-1

Units with external dosing

bt

Beep time

bt10

Beep time when machine restarts

dp

Program by default

1 … 4

Selected program by default

3

3

UCM

Locking the coin

meter box

UCM-0

Coins/tokens accepted at the beginning of the

cycle regardless of the status of the door and the

program selected.

UCM-1

Coins/tokens accepted at the beginning of the

cycle only after the door is closed and the

program selected.

PSH

Order for cycle start

PSH-0

Cycle start by inserting coins

PSH-1

Cycle start by inserting coins and key for the

program selected

SP

Levels of suds

prevention

(EH020 and REM025

models only)

SP-0

Without suds prevention

SP-1

First level of suds prevention

SP-2

Second level of suds prevention

SP-3

Third level of suds prevention

Hr

Program price

according to hour

band

Hr-0

Option not available

Hr-1

Option available

dSP

Temperature display

dSP0

No temperature value displayed

dSP1

Temperature value displayed

Id

Network identifier

Id-0

Disabled communication

Id-1..99

Enabled communication

Indicates default option according to settings.

9.1. Parameters modification

Access to the ADVANCED MODE. Section 5.1. The display shows Pro.

Press key 2 four times. In the display reports CASH, dEmo, InFO, Mod are showed successively.

(In machines with extra options, press Key 2 five times. The displays shows CASH, EoPt, dEmo, InFO and

Mod successively.)

Press the 1 key to display the first parameter.

Modification of operation parameters 31

Cod. 598144

Rev. 12/1218

Temperature unit

The bath water temperature can be displayed in Celsius or Fahrenheit degrees.

OPTIONS

MEANING

C

Temperature unit in Celsius degrees

F

Temperature unit in degrees Fahrenheit